- Process Review and Assessment

- Sewage and Wastewater Management and Operation

- Planned Preventative Maintenance

- 24hr Emergency Call-Out

- Tankering and Jetting Operation

- UKAS Accredited Laboratory Effluent Testing

- Sewage and Drainage Asset Management

- Plant and Equipment Repair and Refurbishment

- Installation and Commissioning

- Forecourt Services

- Spares and Replacement Parts

- Commercial and Domestic Sewage Systems

- Grease Management

- Plant Hire and Rental

KEE Services recognises that the maintenance and operation of wastewater treatment equipment is a specialised task. With its extensive on-site servicing of all types of wastewater treatment and pumping equipment, its engineers have the knowledge necessary to protect customers’ investment and the environment.

KEE Services offers planned maintenance programmes, ranging from an annual visit to full plant operation. Its aim is to respond to all of your servicing and maintenance needs.

The KEE nationally-based Services Team of over 30 fully trained and certified British Water accredited engineers operates on both a local and regional basis to ensure a prompt and reliable service.

Management and Operation . . . a long-term commitment to you

All mechanical and electrical systems require regular maintenance to ensure a long, trouble-free and cost-effective operational life. Regular servicing can prevent the occurrence of costly problems.

- KEE Services Ltd offers maintenance, operation and breakdown services for all types of treatment plant and pumping equipment, from all manufacturers.

- KEE technicians are trained in long-term servicing and are currently maintaining over 8,000 installations within the UK.

- Sound mechanical and electrical experience, combined with application knowledge, means they can identify problems early on and recommend the best solutions.

24hr Emergency Call-Out . . . a national company with local knowledge

KEE’s nationwide team of technicians operates on a local basis, so that wherever you are in the country, you can be assured of prompt service. Because they work in specific regions, KEE’s technicians have a good understanding of the conditions and legislations in your particular area.

A central call centre is staffed by people who are trained to understand the common problems you may experience and give you advice. From here, the nearest available technician can be contacted, thereby making the most of the extensive resources to solve your problems quickly.

Preventative Maintenance . . . a tailored approach

Focusing on your particular issues, KEE can help prevent potential problems, before they become costly or hazardous situations. From installation of the most appropriate equipment to routine inspections and maintenance, different clients have different needs. However, the aim is always the same – to provide you with competent support for the long-term management of wastewater.

Service, Maintenance and Operations

The KEE service package comprises a complete range of options, from servicing and repairs through to regular maintenance and full plant operation.

Site Assessment

KEE technicians can assess your site if it is not linked to mains drainage and can recommend the most appropriate and effective systems to suit the local ground conditions.

When considering the purchase of a new house, office or industrial unit, KEE can assess the local ground and offer options for the discharge of the wastewater.

Installations and Commissioning

KEE technicians can supervise the installation of your equipment, to make sure it is completed effectively. Correct installation will help avoid problems and unforeseen future costs.

Forecourt Services

From installation and commission of oil level and fuel tank alarms to servicing and routine operation checks, KEE has SPA trained technicians who can provide you with a complete service. They can also carry out routine checks on coalescer and closure devices on Class 1 and 2 separators.

Service and Maintenance Contracts

Routine visits will help keep your equipment in the best order and KEE has a range of contracts to choose from. As well as servicing its own systems, its technicians are trained to maintain those of other manufacturers, giving you a comprehensive service.

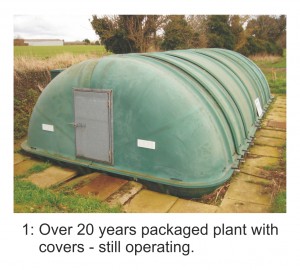

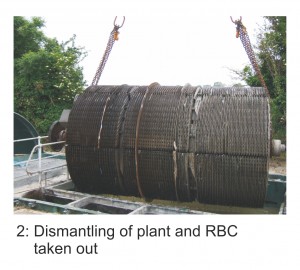

Refurbishment and Upgrades

As your needs change, KEE is on hand to offer advice on how to refurbish or upgrade existing equipment to meet those needs, from minor improvements to enhance the functioning of a plant, the addition of extra units, catering for expansion or to provide a higher quality of effluent.

Sludge Tankering and Jetting services

Residential or commercial, customers can save time and money by having KEE Services de-sludge and service your treatment plant.

Plant Hire and Rental

KEE offers one of the largest ranges of Process Equipment, Plant and Technologies for hire in the industry, available to the domestic, industrial and civil engineering markets

Grease Management

- KEE Class 1 and Class 2 grease separator for physical solids and grease removal.

- KEE Bio-Guard – for Biological Solution to Fat, Oil and Grease.

Total Management

KEE can offer a bespoke service package, tailored to individual requirements. Its total support means that you can expect peace of mind, knowing that it is working to protect your equipment and your environment. Whether a single or multi-site operation anywhere in the UK, KEE can design a package to best suit your requirements, including routine inspections, maintenance, operation, emergency call-out services and supply of spares.

For full details of KEE Services visit their website.