Click on images below to view leaflets.

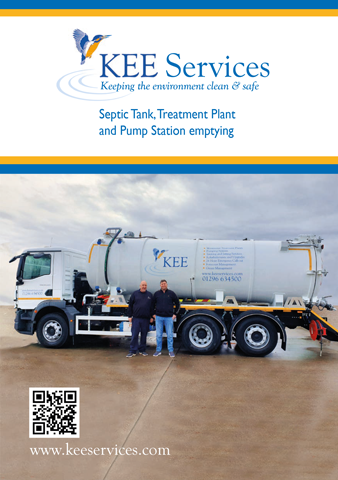

The KEE Services Team receive a new tanker

The KEE Services Team are now on the road serving their valued customers with the addition of their new tanker.

If you require KEE Services for any off-mains drainage enquiries, please contact the team on : 01296 634500

or email: sales@keeprocess.com

KEE are supporting the life changing work of the Great Ormond Street Hospital

If you would like to support Great Ormond Street Hospital you

can donate here:

www.justgiving.com/KEEServices

Water magazine portal information on the KEE Group

KEE Group Limited | Water Magazine

Made up of KEE Process & KEE Services Limited

Specialists in Domestic & Industrial Sewage Treatment Plants and Pump Stations

Specialists in servicing sewage treatment plants and pump stations

Check out the KEE profile on the UK Projects online portal

Update of expired sewage treatment facility with a KEE Rotating Biological Contactor prevents pollution to River Dene

KEE RBC replacing expired Sewage Treatment Facility under Section 101a of the Water Industry Act

The picturesque village of Walton is located within the heart of Warwickshire adjacent to the River Dene. The existing privately owned sewage treatment facility located on the bank of the River Dene was life expired and would often flood, resulting in pollution to the river. An application was made to Severn Trent under Section 101a of the Water Industry Act to provide a first-time sewage connection for all 20 properties in Walton village with a population of approximately 70 people. Due to the remote location of the village, a connection onto the existing Severn Trent sewer network, either gravity sewer or a pumped solution, was not deemed feasible. Therefore, the proposal was for the installation of a new rotating biological contactor (RBC) to replace the existing treatment facility.

Full project case study, click here

For KEE RBC information

click here

For more information on KEE technology and services please visit our website or call 01296 634500

KEE design and manufacture a gravity NuDisc® wastewater treatment plant to replace a decades old treatment system.

KEE’s solution was to provide a gravity system which incorporated all the clients wishes for ongoing operation and maintenance with enhanced Health and Safety features all within a smaller footprint than the existing treatment works.

Marc Goldby – Head of Home Investment at Bromford commented, “KEE have been an integral partner in Bromford’s wastewater investment programme, consistently providing a first class service as highlighted by the project at Woodmancote, meeting all of our requirements and one both we and our customers can be confident in for years ahead.”

For more information on KEE technology and services please visit our website or call 01296 634500

KEE is protecting the environment with two NEW wastewater treatment product ranges

For applications up to a population equivalent of 50

KEE NuPump:

This is a totally self-contained, covered, single piece packaged pump station fabricated in lightweight, corrosion-resistant and tough Tank Grade polyethylene, it is virtually silent and odour free.

The KEE NuPump is easy to install, with minimal site work and is suitable for small to medium flows of up to population equivalent of 50 in single-piece configuration.

Extremely low power demand and low maintenance costs, together with longevity ensure a lowest lifetime cost.

KEE NuFlow:

This is a totally self-contained, covered, single piece packaged treatment plant fabricated in moulded one-piece durable medium density polyethylene material, corrosion-resistant. it is silent and odour free.

The KEE NuFlow is easy to install, with minimal site work and is suitable for small to medium flows of up to population equivalent of 50 in single-piece configuration.

Mechanically reliable with no internal electrical or moving parts therefore low maintenance costs, together with longevity ensure a lowest lifetime cost.

For further details call 01296 634500

E: sales@keeprocess.com W: www.keeprocess.com

Why you should choose KEE in 2021

Our specialist knowledge and expertise is derived from over 65 years’ experience in the development, design, manufacture, servicing, maintenance and operation of wastewater treatment systems and equipment. Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Contact us to discuss how we can help you on:

01296 634500, or visit our

website – www.keeservices.com

Happy Festive Season and a Prosperous New Year

Closing on 24th December, opening again on 4th January 2021.

Closing on 24th December, opening again on 4th January 2021.

Normal hours on 24th , 29th, 30th, & 31st December,

Normal hours on 24th , 29th, 30th, & 31st December,

back to normal on 4th January 2021.

For managed contracts, please refer to your

account manager for out of hours service.

Full information on KEE services and process technology, is available on our WEBSITE