Click on images below to view leaflets.

Category Archives: Grease Separation

At KEE we are ‘open for business’

The KEE Group provide solutions to the Wastewater Treatment Industry for all domestic, commercial and industrial applications. CLICK HERE

- KEE are committed to providing total customized solutions for the treatment of wastewater and have the most innovative systems to treat every situation.

- KEE leads the country in the supply, maintenance and operation of wastewater treatment systems and can provide you with the best solution.

- KEE systems are also available for hire.

KEE Services comprises a complete range of options, from simple servicing and repairs through to full service, maintenance and plant operation, including:

- On-Site Plant Operation

- Facilities Management

- Emergency Service

- Planned Maintenance

- Breakdowns

- Equipment Refurbishment

- Spares

- BioGuard™ Grease Digester

- Ancillary Products

KEE wastewater technology provide total solutions for the treatment of wastewater:

- Process Engineering

- Project Management and Turnkey Projects

- Pumping Equipment

- Dispersed Air Floatation (DAF)

- Anaerobic treatment for industrial wastewater

- Sequencing Batch Reactor

- NuDisc™ and Packaged RBC Systems

- Submerged Aerated Filters (SAF)

- Oxidation Ditch

- Installation and Commissioning

- Nutrient Removal

For full information on our KEE services and process technology, visit our WEBSITE.

The Biological Solution against Fat, Oils and Grease (FOG) – KEE BioGuard the grease digester

The biological solution against fat, oils and grease that ensures a clear flow to preventing blocked drains.

With the ever increasing changes and tightening of regulations regarding the safe disposal of Fats, Oils and Grease (FOG), the maintenance and management of Grease Traps and Grease Separators has become a regular part of our customers’ waste removal service requirement.

For many catering establishments such as, pubs, hotels and restaurants, the build up of FOG is an everyday occurrence, due to food preparation and dish washing.

Left untreated, it can lead to a mixture of problems, many of which can result in bad smells, hygiene worries, unhappy customers, environmental issues, costly emergency call outs and lost revenues.

FOG does not dissolve in water, it floats on the surface and coats drain walls, pump wells and grease separators. If left untreated, it accumulates, solidifies and can eventually form what is known as ‘Fatbergs’ in the wastewater drainage system.

Although equipment such as Grease Separators and Grease Traps will separate the grease from the wastewater, the regular cost and hasstle of removing and disposing of the grease remains an on-going maintenance issue.

KEE’s Bioguard system is different as it dissolves the fats, oil and grease by ‘digesting the grease’ and dismantling the cellular composition of the FOG permanently.

The great news is that KEE’s Bioguard system is small, compact, quick and easy to install and the solution is 100% biodegradable, making it safe to use in the kitchen environment, protecting the health and welfare of your staff.

For more information visit our website or call KEE Services on:

01296 634500

![]()

KEE’s Commitment to Environmentally Sustainable Procurement and Fair Trade

One of KEE’s core company values focuses around Environmental Sustainability. As a business, we recognise our obligations to consider the environmental impact the materials we source and the products we produce have on the environment and, we aim to reduce the impacts & ensure environmental sustainability.

Fairtrade is about better prices, decent working conditions and fair terms of trade. It’s about supporting the development of thriving communities so that they have more control over their futures and protecting the environment in which they live and work.

KEE Process Ltd & KEE Services Ltd aim to ensure that we will play our part in reducing risks:

- Use fewer resources and less energy through continuous improvement and the use of innovative solutions.

- Procure all timber and timber products from legal and sustainable sources, and procure with a preference other construction materials from recognised responsible sourcing schemes.

- Specify and procure materials and products that strike a responsible balance between social, economic and environmental factors and generate benefits to society and the economy.

- Use resource-efficient products and give due consideration to end-of-life uses.

- Influence, specify and source increasing amounts of materials which can be reused, and consider future deconstruction and recovery of resources to embrace the circular economy to leave a sustainable legacy across the built environment.

- Where possible, provide opportunities for small and medium sized enterprises (SMEs) increase the use of social enterprises, support local employment, diversity and training and work collaboratively with the voluntary sector, especially those near to our offices and operations.

- Ensure that fair contract prices and terms are applied and respected, and that ethical, human rights and labour standards are met, in line with the United Nations Global Compact principles.

- Source goods, works and services that embody our environmental policy, health & safety policy and support the delivery of our Sustainable Development Strategy.

We believe our commitment to these values is one of a number of ways in which KEE, everyone within the company, and all our customers can demonstrate social, environmental and economic responsibility. Our business like all others changes and evolves over time, but our core values remain the same.

For more information, please call 01296 634500 or visit our website.

WHY CHOOSE KEE?

KEE was formed as a family run business back in 1955. Although the industry has changed significantly since then, KEE’s ‘family’ company culture continues to focus on ethical business values and an integrity and commitment to delivering high quality products and services to its customers.

KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the development, design, manufacture, installation, servicing, maintenance, refurbishment and operation of wastewater treatment systems and equipment.

Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Operation, Service & Maintenance of Wastewater Equipment

- KEE Engineers have decades of experience in maintaining of all types of sewage treatment equipment and pumping stations, providing peace of mind that your equipment is in safe hands.

- KEE operate to the highest standards of practice. We are BSI ISO 9001 Quality Management accredited in the commissioning, servicing, maintaining and operating of domestic and industrial wastewater treatment systems. Our Service Technicians are DBS checked and British Water accredited.

- KEE believes in creating the very best products to protect the environment. Our KEE designers undertake on-going research and development to continue delivering process and cost efficiencies using the very latest advancements in design technology. For example, this year we launched a new Tertiary Filter and UV light disinfection system for the KEE NuDisc-R® which offers superior wastewater quality discharge.

- KEE Engineers only fit genuine KEE approved parts, selected for their quality, durability and value for money.

- KEE’s annual ‘Maintenance Service’ includes a comprehensive 127 point checklist report, providing a full analysis of the electrical, mechanical and operational condition and performance of your plant.

- KEE’s Service Managers and Engineers offer professional advice on looking after your plant, controlling maintenance costs and avoiding expensive damage to your equipment.

- KEE design and undertake bespoke and standard plant refurbishments and upgrades, meeting the changing needs of our customers and the environment.

An ‘End-to-End’ Service Solution

KEE Services offer a range of maintenance, operation and breakdown services for all types of treatment plant and pumping equipment, from all manufacturers.

- Annual Plant Electrical & Mechanical Service and Maintenance Assessment

- Sewage and Wastewater Plant Management and Operation

- Planned Preventative Maintenance

- Nationwide 24hr Emergency Call-Out

- Plant and Equipment Breakdown Repair

- UKAS Accredited Laboratory Effluent & Water Sampling

- Tankering and Jetting Advice, Scheduling and Operational ‘Supervision’ Service

- New Plant Supply, Installation and Commissioning

- Forecourt Services

- KEE Approved Spares and Replacement Parts

- Commercial and Domestic Sewage Systems

- Grease Management via Dosing/Physical Removal

- Domestic and Industrial Plant Hire and Rental

KEE know that professional maintenance will extend the life of your plant and minimise the risk of serious damage and breach of environmental consents.

Our nationwide team of directly employed regionally based KEE engineers are trusted by over 6,000 customers.

So . . . whether you have a single, or multi-site operation across the UK, KEE can design and deliver a tailored service solution to meet your requirements and liaise with the Environment Agency on your behalf if required.

For more information, please call Julie or Natasha on

01296 634500 or email us at sales@keeservices.com

KEE Parts and Service, Maintenance and Operation

KEE Services Limited Online Shop for WwT Plant spares

KEE Services Ltd – offers maintenance, breakdown services and plant operation for all types of treatment plant and pumping equipment, from all manufacturers. KEE technicians are trained in long-term servicing and look after 8,000 installations in the UK. KEE also operate ‘out-of-hours’ 24 hour call centre.

KEE Wastewater Treatment Systems can be configured for BOD removal and/or nitrification and/or de-nitrification and can include a built-in or modular physical-biological tertiary filter. UV disinfection can also be included into the packaged plant to enable non-portable water re-use.

KEE PROCESS LIMITED and KEE SERVICES LIMITED –

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.

KEE Bio-Guard, the biological solution against Fat, Oil and Grease (FOG).

The Biological Solution against Fat, Oil and Grease.

To maintaining a clear water flow from Fat, Oil and Grease KEE Bio-Guard ensures:

- Prevention of unpleasant odours

- Elimination of expensive call-outs

- Free running drains

- Conformity with effluent discharge regulations

- An environmentally friendly response to pollution

- Peace of mind.

KEE Bio-Guard is a long-lasting solution which needs little further maintenance. Completely biodegradable, and is safe to use in the kitchen environment

KEE Bio-Guard is the biological alternative to prevent blocked drains, offensive smells and maintenance of grease traps.

KEE Wastewater Treatment Systems can be configured for BOD removal and/or nitrification and/or de-nitrification and can include a built-in or modular physical-biological tertiary filter. UV disinfection can also be included into the packaged plant to enable non-portable water re-use.

KEE PROCESS LIMITED and KEE SERVICES LIMITED

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.

THE KEE GROUP – WHO AND WHAT ARE THEY?

ENVIRONMENTAL ISSUES affect us all equally and most of us have a heightened awareness of the environmental impact on our planet. All of us need stable climate weather patterns, clean air and clean water for survival and we at KEE play our role in securing the cleanliness of our water sources.

KEE GROUP, comprising of KEE Process Limited and KEE Services Limited is a privately-owned British company which, for the past 60 years, has been at the forefront of providing affordable solutions for the treatment of wastewater and its discharge into a watercourse or the aquafer.

We all take for granted a clean water supply but the treated wastewater discharged into the environment, in almost all cases, does become a source for that clean water supply. Consequently over many years, quality requirements for discharge of treated effluent to watercourses have gradually been tightened up and at present these quality requirements do not only relate to reduction of oxygen demand and suspended solids but also include nutrient removal such as total nitrogen and phosphorus. Behind the scenes at KEE, we have been busy making sure that we continue to rise to the challenge of the stringent requirements for discharge of treated effluent from Municipal and Industrial wastewater treatment systems.

To support this mission, KEE has patented and introduced a large range of technologies and hardware to provide systems for treating small and large flows. The small flows are treated using KEE NuDisc® single-piece packaged plants, which are designed and engineered to provide value for money and are configured to operate with minimum day-to-day intervention. In addition to these single piece KEE NuDisc® packaged plants, there is the modular system arrangement, based on various technologies such as RBC, SAF and Activated Sludge plants. These single piece and modular packaged plants are versatile in their application and are able to provide nutrient (total nitrogen and phosphorus) reduction in the packaged plant configuration.

KEE also provides and supplies solutions for larger flows, which may involve construction of a plant from modular components and hardware, or a totally on-site built system. KEE has all the technology options at its disposal and is therefore able to process-engineer the optimum solution for the application, taking into account the customer’s needs and the site requirements. To facilitate this, KEE provides the services of its Process Engineers to evaluate the site requirements and the treatment objectives. KEE wastewater treatment technologies include Submerged Aerated Filters (SAF), Rotating Biological Contactors (RBC), Extended Aeration Activated Sludge Treatment Plant, Sequencing Batch Reactor Activated Sludge Plants, Oxidation Ditch, Ultra-Fine Filtration Modules, Dispersed Air Flotation (DAF and Microfloat) and Anaerobic Reactor for treatment of high-strength industrial wastewaters. The suitability of any one, or a combination of these technologies and unit operations, will be assessed to arrive at the most optimised solutions.

KEE has introduced various features in the hardware offering the above technologies and these include:

- Patented Managed Flow features in the system enabling hydraulic and organic attenuation of loads.

- Removable fine bubble membrane diffusers in SAF Systems without the need to remove the media or empty the tank.

- Highly efficient and cost effective dispersed air Microfloat® System for removal of fat, oil, grease, suspended solids, BOD and COD from industrial wastewater discharge.

Introduction of high-efficiency surface-mounted dual mode processor designed to provide efficient mixing and fine bubble aeration of deep basin activated sludge systems.

A good and well-executed engineered solution for treatment of wastewater is only part of the total ongoing requirement for our clients. To complete the package, KEE also offers its clients the basic service and maintenance of hardware and equipment, or can take over the total operation and maintenance of the plant on behalf of the client. The objective for KEE is to provide their customers with the lowest lifetime cost solution and KEE rises to the challenge by offering to operate the plant at a fixed price. This gives the client complete peace of mind. KEE also offers to operate and maintain plants supplied by other manufacturers after an initial survey and evaluation of the system already installed.

The Literature site includes a complete set of KEE literature and Press information on all their technology and services offered, including KEE NuDisc®, KEE EnviroSAF, KEE Microfloat® Dispersed Air Flotation System and the Triton® Dual Mode Processor for aeration and mixing of activated sludge in conventional and extended aeration plants and oxidation ditches.

To see the capabilities of the KEE Group of companies please visit the KEE Group website.

KEE SERVICES LIMITED – THE ONE-STOP-SHOP for Service, Operation and Maintenance for all Wastewater Treatment Assets.

KEE Services, part of the KEE Group recognises that the correct management, service and maintenance of sewage and wastewater assets is both an important and a specialised task. With its extensive ‘In-House’ capabilities, KEE Services is able to provide the effective management, service and maintenance of all types of sewage treatment and wastewater technologies and pumping stations. Furthermore, it is able to provide a professional and cost-effective service to its UK-wide customers.

Located across the UK, its 24 regional service engineers have the extensive knowledge and experience necessary to protect customers’ investment and the environment, whilst prolonging the lifespan of equipment. KEE Services further supports its customers during out-of-hours periods by offering a 24-hour manned emergency call-out service.

KEE’s core business capabilities for the management, operation, service and maintenance, of the wastewater industry cover:

- Sewage and wastewater treatment plants

- Pumping stations

- Grease management systems for commercial kitchen facilities

- Tanker and jetting operations

- Drainage clearance.

In addition to its ‘Core’ business, KEE is also able to provide a UK-wide service and maintenance role :

- Water softening plant

- Clean water booster plant.

KEE Services has over 60 years of experience in the management, service and maintenance of over 8000 UK sites, encompassing a wide range of sewage and wastewater treatment technologies. With its Headquarters based in Aston Clinton, KEE Services has five Regional Service Centres in the UK, providing flexible and tailor-made service, operation and maintenance packages to meet specific customer requirements, as below:

Premier Contract

The ‘Premier’ service contract includes routine and planned inspection of the wastewater treatment plant. Service visits include the inspection, adjustment and maintenance of electro-mechanical items, assessment of the treatment process and effluent quality.

With this basic service package, any spare parts required are charged as extras, with breakdown call-outs being charged separately for labour and travel costs.

Elite Contract

The ‘Elite’ service contract provides complete peace of mind as annual budgeting is made easier. There are no hidden or extra costs at all. Included in this package is the same level of electro-mechanical inspection as offered with the ‘Premier’ service contract. In addition, the ‘Elite’ service contract covers for all the following items:

- Travel costs

- Labour costs

- Consumable items

- Spare parts

- Emergency breakdown call out.

Managed Contract

Can include PPM, Servicing and Plant Operation

For customers who have multiple sites or large single wastewater installations, KEE Services offers a fully comprehensive contract for the complete operation of these plants. Each O&M contract is assigned a dedicated Contracts Engineer who reports directly to the client on all aspects of the treatment plant.

Additional special tasks can include desludging, laboratory sampling. jetting etc.

A maintenance log book is kept on site and updated with every visit providing the assurance that the plant is being effectively managed and receiving the necessary maintenance required to achieve optimum operating conditions.

Call 01296 634500 to discuss what we can do for you, or go to the KEE Services website for more information.

KEE MICROFLOAT DISPERSED AIR FLOTATION TECHNOLOGY REDUCES POLLUTION

KEE continually introduce improvements to effluent treatment technology in a bid to minimise environmental pollution from wastewater.

Many industrial processes, particularly food processing, drinks/brewery and dairy, generate a large volume of effluent that is discharged into the sewer. The raw wastewater has high biological oxygen demand (BOD), high chemical oxygen demand (COD) and Fat, Oil and Grease (FOG). To reduce environmental pollution, companies often pre-treat the wastewater before the wastewater is discharged into the sewer.

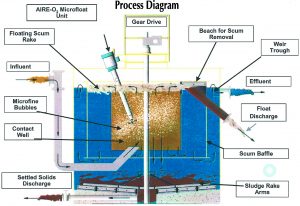

Cut-away view of the KEE Microfloat Dispersed Air Flotation Technology.

Process diagram of the KEE Microfloat technology.

This food processing plant reduced surcharges with the KEE Microfloat.

Until now, a system known as Dissolved Air Flotation (DAF) has been used to do this. The conventional DAF system uses a high-pressure pump, venturi system and pressure vessel to dissolve air into the wastewater. The solution of air and water is stabilised in a pressure vessel under high pressure. A stream from the pressure vessel is discharged into a separating vessel where the air comes out of solution and is released as a fine bubble spray. These bubbles greatly reduce the pollutants by floating them to the surface where they are removed by equipment designed to remove the floating layer.

The KEE Microfloat system achieves the same result without the need to use a high-pressure pump and venturi. Instead, it incorporates a patented system from Aeration Industries that uses a low-power motor. A specially designed propeller disc on the aerator’s shaft produces extremely fine bubbles and transfers these 10-50μm air bubbles into the water through special ejectors.

The whole system is mounted in the circular flotation tank or could be mounted in a rectangular tank be retro-fitted into an existing DAF system.

Some major advantages of the KEE Microfloat system are that it:

- Removes in excess of 90% of fats, oils and grease (FOG).

- Substantially reduces the BOD and COD of the effluent.

- Eliminates the need for fine screens either before or after fat traps.

The KEE Group of Companies is committed to providing a customised approach to domestic, commercial and industrial wastewater treatment applications. With over 60 years’ experience in the development, design and manufacture of equipment, KEE has installed more than 350,000 solutions worldwide.

To see the capabilities of the KEE Group of companies please visit the KEE Group website