KEE offer another revolutionary fixed film technology using compressed air. Traditionally, SAF systems with structured media have been offered with fine bubble membrane diffusers, with the drawback that access to diffusers was difficult. Until now it has been necessary to remove media and empty the reactor tank of wastewater to access the fine bubble membrane diffusers.

KEE have patented new technology, making it possible to access the fine bubble membrane diffusers without the need of emptying the SAF tank, or removal of the media. Whilst one set of fine bubble membrane diffusers is being maintained the rest of the SAF plant can continue to function and treat the wastewater. This negates the need to empty or hire a temporary plant while maintenance is being carried out.

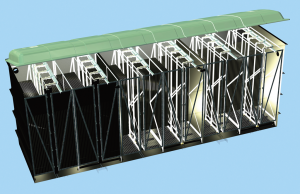

Cut-away view of the KEE EnviroSAF

KEE have installed 2500 PE SAF Systems in Scandinavia using this new EnviroSAF technology and also have built plants for UK Water plc..

The KEE EnviroSAF uses patented structured media which has a profile in its shape to induce velocity and pressure gradients in the air/water mixture flowing through the media. This concept enhances mixing and is responsible for keeping the biomass film on the media active and aerobic. KEE have offered SAF Systems for many years and have built100’s of containerised mobile plants for Work and Army Camps, where the systems were designed to be above ground as they needed to be mobile. Access to diffusers was therefore easy.

KEE have also installed SAF Systems in Northern Ireland where the final effluent quality achieved is extremely high, with BOD less than 4mg/litre, ammoniacal nitrogen less than 2mg/litre, phosphorus less than 4mg/litre and suspended solids less than 10mg/litre. The EnviroSAF technology offers all the process stability of fixed film reactors, but with the added advantage of using fine bubble diffused air, patented structured PVC media and the ease of access for maintenance of diffusers without the need to remove the media and emptying the EnviroSAF tank.

The KEE Group of Companies is committed to providing a customised approach to domestic, commercial and industrial wastewater treatment applications. With over 60 years’ experience in the development, design and manufacture of equipment, KEE has installed more than 350,000 solutions worldwide.

To see the capabilities of the KEE Group of companies please visit the KEE Group website

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

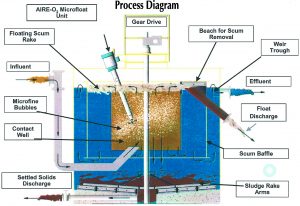

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.