KEE continually introduce improvements to effluent treatment technology in a bid to minimise environmental pollution from wastewater.

Many industrial processes, particularly food processing, drinks/brewery and dairy, generate a large volume of effluent that is discharged into the sewer. The raw wastewater has high biological oxygen demand (BOD), high chemical oxygen demand (COD) and Fat, Oil and Grease (FOG). To reduce environmental pollution, companies often pre-treat the wastewater before the wastewater is discharged into the sewer.

Cut-away view of the KEE Microfloat Dispersed Air Flotation Technology.

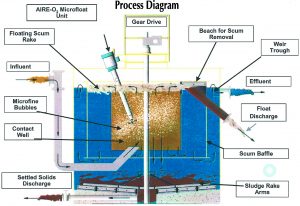

Process diagram of the KEE Microfloat technology.

This food processing plant reduced surcharges with the KEE Microfloat.

Until now, a system known as Dissolved Air Flotation (DAF) has been used to do this. The conventional DAF system uses a high-pressure pump, venturi system and pressure vessel to dissolve air into the wastewater. The solution of air and water is stabilised in a pressure vessel under high pressure. A stream from the pressure vessel is discharged into a separating vessel where the air comes out of solution and is released as a fine bubble spray. These bubbles greatly reduce the pollutants by floating them to the surface where they are removed by equipment designed to remove the floating layer.

The KEE Microfloat system achieves the same result without the need to use a high-pressure pump and venturi. Instead, it incorporates a patented system from Aeration Industries that uses a low-power motor. A specially designed propeller disc on the aerator’s shaft produces extremely fine bubbles and transfers these 10-50μm air bubbles into the water through special ejectors.

The whole system is mounted in the circular flotation tank or could be mounted in a rectangular tank be retro-fitted into an existing DAF system.

Some major advantages of the KEE Microfloat system are that it:

- Removes in excess of 90% of fats, oils and grease (FOG).

- Substantially reduces the BOD and COD of the effluent.

- Eliminates the need for fine screens either before or after fat traps.

The KEE Group of Companies is committed to providing a customised approach to domestic, commercial and industrial wastewater treatment applications. With over 60 years’ experience in the development, design and manufacture of equipment, KEE has installed more than 350,000 solutions worldwide.

To see the capabilities of the KEE Group of companies please visit the KEE Group website