Click on images below to view leaflets.

Category Archives: KEE Aeration Systems

At KEE we are ‘open for business’

The KEE Group provide solutions to the Wastewater Treatment Industry for all domestic, commercial and industrial applications. CLICK HERE

- KEE are committed to providing total customized solutions for the treatment of wastewater and have the most innovative systems to treat every situation.

- KEE leads the country in the supply, maintenance and operation of wastewater treatment systems and can provide you with the best solution.

- KEE systems are also available for hire.

KEE Services comprises a complete range of options, from simple servicing and repairs through to full service, maintenance and plant operation, including:

- On-Site Plant Operation

- Facilities Management

- Emergency Service

- Planned Maintenance

- Breakdowns

- Equipment Refurbishment

- Spares

- BioGuard™ Grease Digester

- Ancillary Products

KEE wastewater technology provide total solutions for the treatment of wastewater:

- Process Engineering

- Project Management and Turnkey Projects

- Pumping Equipment

- Dispersed Air Floatation (DAF)

- Anaerobic treatment for industrial wastewater

- Sequencing Batch Reactor

- NuDisc™ and Packaged RBC Systems

- Submerged Aerated Filters (SAF)

- Oxidation Ditch

- Installation and Commissioning

- Nutrient Removal

For full information on our KEE services and process technology, visit our WEBSITE.

KEE’s Commitment to Environmentally Sustainable Procurement and Fair Trade

One of KEE’s core company values focuses around Environmental Sustainability. As a business, we recognise our obligations to consider the environmental impact the materials we source and the products we produce have on the environment and, we aim to reduce the impacts & ensure environmental sustainability.

Fairtrade is about better prices, decent working conditions and fair terms of trade. It’s about supporting the development of thriving communities so that they have more control over their futures and protecting the environment in which they live and work.

KEE Process Ltd & KEE Services Ltd aim to ensure that we will play our part in reducing risks:

- Use fewer resources and less energy through continuous improvement and the use of innovative solutions.

- Procure all timber and timber products from legal and sustainable sources, and procure with a preference other construction materials from recognised responsible sourcing schemes.

- Specify and procure materials and products that strike a responsible balance between social, economic and environmental factors and generate benefits to society and the economy.

- Use resource-efficient products and give due consideration to end-of-life uses.

- Influence, specify and source increasing amounts of materials which can be reused, and consider future deconstruction and recovery of resources to embrace the circular economy to leave a sustainable legacy across the built environment.

- Where possible, provide opportunities for small and medium sized enterprises (SMEs) increase the use of social enterprises, support local employment, diversity and training and work collaboratively with the voluntary sector, especially those near to our offices and operations.

- Ensure that fair contract prices and terms are applied and respected, and that ethical, human rights and labour standards are met, in line with the United Nations Global Compact principles.

- Source goods, works and services that embody our environmental policy, health & safety policy and support the delivery of our Sustainable Development Strategy.

We believe our commitment to these values is one of a number of ways in which KEE, everyone within the company, and all our customers can demonstrate social, environmental and economic responsibility. Our business like all others changes and evolves over time, but our core values remain the same.

For more information, please call 01296 634500 or visit our website.

KEE Triton® – Mountmellick Wastewater Treatment Plant Upgrade – The installation of new aeration and mixing units to reduce the carbon footprint and improve plant performance.

Background

Mountmellick village is located approximately 15 miles northwest of Portlaoise, County Laoise, Republic of Ireland. As with all Irish towns, Mountmellick has grown greatly over the years. The existing plant was designed and installed in the mid 1970s, with further works being added later, the last being a sludge dewatering plant.

The existing plant design consisted of:

- A Wham Mechanical Screen

- An Oxidation Ditch for biological treatment. A 60m long ‘Race Track’ shaped ditch, each lane measuring 7m wide. The total average depth of the ditch was 1.57m with a total volume of 1,340m³.

- Horizontal Brush Aeration System. As was the practice during the 1970s, consisting of 4 horizontal rotors, each 2m in length

- Two final settlement tanks and sludge dewatering works.

- An ‘activated sludge process’for the biological treatment stage.

The Challange

The design capacity of the works was 5,000PE and the discharge consent was 20mg/l BOD (Biological Oxygen Demand) and 30mg/l SS (Suspended Solids). The brush rotor aeration capacity had proved inadequate and was supplemented by Venturi Aerators. The combined horizontal brush and Venturi Aeration systems were unable to support the process oxygen demand and could not provide the necessary velocity profile in the ditch to ensure the minimum vital mixing requirement of the ditch contents. Consequently, the plant was failing consent.

In addition to the problems associated with the failure of consent, the high power demand to run the aeration system at Mountmellick (i.e. two 7.5kW drives for each horizontal brush rotors and two 13.50kW drives for each Venturi Aerator) also made it expensive to run at existing capacity. However, the need to increase plant capacity from 5000PE to 7000PE meant that the high power supply to the existing plant provided an opportunity to review the whole process performance of the aeration system and deliver a solution to reduce carbon footprint.

KEE Process was contacted by Laois County Council, to discuss how the Triton® aerators and mixers, could overcome the current process load issue facing the Mountmelick plant and explore the option to save power and increase the plant capacity.

After discussions with Laois County Council and their consultants at Nicholas O’Dwyers, KEE visited the site to review the existing plant design and formulate a proposal.

The Solution

After further liaison and evaluation of the actual dissolved oxygen requirements, it was agreed that the plant upgrade should be carried out in two phases using the KEE Process Triton® dual mode, fine bubble aerator/mixer.

- Phase 1 upgrade – To address the urgent need to increase the process performance of the plant to meet the required environmental discharge consent and also reduce the overall carbon footprint.

- Phase 2 – To increase the capability to upgrade the plant capacity upgrade from 5000PE to 7000PE and reduce maintenance requirements.

Based on the current load and the 20mg/l Biological Oxygen Demand consent for Phase 1, it was necessary to install four 3.7kW Tritons® to provide the supplemental Dissolved Oxygen and all the mixing for the oxidation ditch. These four Tritons® would provide complete mixing of the ditch and generate the optimum horizontal velocity of 0.3m/s to ensure that the suspended solids in the mixed liquor remained in suspension at all times.

Treatment processing target criteria for design upgrade:

Type of wastewater Municipal

Dry Weather Flow (DWF) 1,575m3/day

Full Flow to Treatment (FFT) 3.3 x DWF = 5,184m3/day

Total influent BOD5 load 420kg/day

Total influent nitrogen load 77kg/day

Oxidation ditch approximate volume 1,340m3

Treatment objectives BOD5<20mg/l

SS<30mg/l

(no nitrification)

Although the stated environmental objectives did not require nitrification, we knew that the NH4-N in the influent would exert an oxygen demand due to the high retention time of 20 hours (at DWF) in the oxidation ditch. The projected AOR (actual oxygen requirement) of 959kg/day accounts for both carbonaceous BOD reduction and Nitrification. For carbonaceous BOD removal only, the AOR would be 773kg/day.

[Note: AOR is the oxygen required under field conditions of temperature, elevation, desired dissolved oxygen operating concentration].

To provide the projected AOR, eight 3.7kW Tritons® were required, in addition to the existing horizontal brush rotors which would need to be retained. This process upgrade assumed that nitrification would be accepted as a future treatment objective. If this had not been the case then the Tritons on their own would have beeen sufficient to provide all the projected Dissolved Oxhgen (DO) and mixing for the 7000PE capacity.

Supply and Installation

Of all the aeration equipment on the market, Triton® aeration units are the easiest to install. There was no need to decommission the existing plant while installation was being carried out. The Tritons® fine bubble aerators were surface mounted and therefore neither the aeration tank or the oxidation ditch needed decommissioning, emptied, refurbished, refilled and re-commissioned. Tritons® can be bridge-mounted, wall-mounted, float-mounted or guiderail-mounted for SBR configuration.

Timing was of the essence to ensure that the treatment objectives were met and therefore the equipment was ordered whilst the installation format was being finalized. At the Mountmellick site Laois County Council and Nicholas O’Dwyer used a novel adaptation to use a ‘float-mount’ option where the floats were anchored to a steel bridge across the ditch with ‘H Frames’ attached to the bridge. This gave the operators the option to have fluctuating water levels as the H frame pivoted the Triton® floats to the bridge. The existing DO probes were used to control the brush aerators through the variable speed drives and, if the DO remained high, the Triton® blowers could be similarly controlled through the DO probes. At least four Tritons® had to be operating in the mixing mode to completely mix the ditch contents and therefore for Phase 1, the control philosophy was designed only to control the Triton® blowers operation to maintain the DO at between 1 and 2 mg/l.

After the Phase 1 installation was completed and within 20 minutes of the four Tritons® being commissioned, the mixed liquor DO concentration started to rise and it was evident that the units were re-suspending solids that had been settled out in the bottom of the ditch previously. Within two days of commissioning, the four Tritons® units were achieving 1-2mg/l DO constantly, with the existing brush rotors only coming on to assist at times of heavy load when the DO concentration started to drop.

Four out of the eight Tritons® for Phase 2 were operated in aeration and mixing mode at all times and the other four Tritons® were installed to operate in mixing and/or aeration mode when required. To ensure an even use, it was also decided that the Triton® operation would be alternated in ‘duty’ and ‘assist’ mode.

For Phase 1 the installed power was reduced from 42kW to 30kW and the treatment objectives were all achieved. Furthermore, the energy efficiency gains and optimisation objectives were achieved by controlling the aeration mode to provide oxygen as and when required whilst the mixing mode was always maintained to ensure the process performance. Thus, an energy saving over 28.5% was achieved and at the same time the environmental objective for effluent quality was met.

Phase 2 was designed to deliver the energy efficiency gains and carbon footprint objectives. The 45kW total installed power for Phase 2 provided a 40% increase in plant capacity whist requiring only a 3kW increase in power.

The carbon footprint can be further reduced if, as required by the consent for discharge, nitrification of the effluent was not pursued.

For more information on KEE Tritons® or any other wastewater treatment equipment and systems, please refer to our website at keegroup.com or call us on 01296 634500.

3.7kW Tritons® on a tri-pontoon float in position and fastened to the access gantry. The Triton® can be bridge or side-wall mounted.

Industrial Wastewater Disposal and Treatment Options – Back to Basics – A Practical Approach from KEE Process Limited

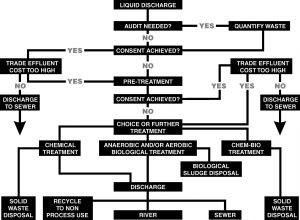

What are the Options

Brewing, winery, soft drinks manufacture, food preparation production and packaging (baking, ready convenience meals, abattoir, meat, poultry and vegetable), dairy (milk processing, cream, cheese and yoghurt production), commercial laundries, pharmaceutical, petrochemical and many other industries are large users of water. This results in large quantities of heavily polluted wastewater for disposal.

UK Water companies and the public bodies responsible for collection, drainage and treatment of wastewater have strict controls on the quantity and the quality of industrial and trade wastewater being discharged into public sewers. Legislation supports them in this. Direct discharge to a watercourse is even stricter and is normally monitored by the National Environmental Agencies and the Environment Agency in the UK. Penalties for transgression can include prosecution, fines, financial loss and can, in some cases, prohibit operations.

Audits

It is always advisable to carry out an evaluation of the processes involved in the core business of an organisation to identify sources of wastewater. An audit would help reduce waste/wastewater and disposal costs, quantify flow rates, solids and organic loads and characterise the wastewater to provide the necessary data for analysing the available disposal options and optimise the design of any on-site treatment plant.

It is useful to be subjective when carrying out an audit to ensure that good housekeeping practices are identified to reduce unnecessary waste which would add to the costs of disposing wastewater generated on site. Process audits should be aimed at identifying the waste, excess use of water and energy. Simple actions, such as installations of energy-saving devices or taps and hose controls and careful disposal of solid waste, can produce both financial and environmental benefits. It would also help to reduce the size of an on-site treatment plant if one was planned and this would result in capital cost savings.

An audit would lead to evaluation of volumetric and organic mass loads for design purposes and would aid in characterising the nature of the waste, to optimise the design for on-site treatment plants.

Public Sewer or Watercourse

Public sewers are convenient for disposal if nearby. Quantity, strength and characteristics of the wastewater need to be considered and consented by Authorities or the Water Company in the UK. If approval is granted and the wastewater meets the criteria set, then sewer disposal would be an obvious choice, but this comes at a cost. High COD (Chemical Oxygen Demand) and suspended solids would lead to high costs in discharging to sewer and reducing these parameters could make significant savings. Partial or full onsite treatment would bring about cost savings to sewer discharge but needs justifying through quantification.

Hygiene versus Convenience

With the food processing, beverage and dairy industry, hygiene is of paramount importance. On-site wastewater treatment may be perceived by management as presenting problems although the risks are small. It is vital that the Operatives normally involved in the process part of the industry, do not need to visit the wastewater treatment plant and the risks to main operation therefore are contained and the operation of the wastewater plant becomes one of non-core features. This can be achieved by having the treatment plant operation undertaken by the maintenance department of the industry or independent operators such as KEE Process Limited who would provide a turnkey solution for designing, supplying, installing and operating a plant for a Client.

Treatment Options: Physical, Biochemical or Combination of Both

Where the decision to treat on-site has been made, the appropriate choice of plant has to be determined. Whether partial treatment or full treatment is installed is usually a matter of economics. A capital outlay is necessary and this must have an acceptable payback period. The treatment options available are Physical, Physical/Chemical, Biological or a combination of all or any of these.

On-site treatment could involve simple physical treatment to remove materials such as gross solids, FOG (Fat, Oil & Grease) and can include pH correction. The equipment may include manual or mechanical screens, grease separators or the newly introduced DISPERSED AIR FLOATATION which is simple, economical and extremely efficient and effective. A component of COD associated with these materials would also be removed by the physical treatment. With DISPERSED AIR FLOATATION up to 30% BOD, 50% COD, 60% TSS and over 90% FOG can be removed physically without the use of chemicals. Better performance can be achieved by using coagulant, flocculants and ploy-electrolytes. In most cases, partial treatment using DISPERSED AIR FLOATATION would achieve the reduction in pollution loads necessary to substantially reduce the cost of discharge of effluent to public sewer. The ownership costs (capital expenditure, servicing, maintenance and operation costs) associated with DISPERSED AIR FLOATATION are usually low. The benefits of cost savings in effluent disposal are high and the capital/operating cost of proving on-site partial treatment can be justified against the ownership costs. Given these benefits it may be sufficient not to invest in further onsite treatment for the effluent to be discharged into public sewer.

However, it may still be necessary or even desirable for the wastewater to be treated further for direct discharge to a watercourse or re-used for non-process operations within the industry. In such a case, full on-site treatment would often justify the capital and operations cost. Cost analysis must also take into account the valuable space required for location of the treatment plant on the core business site.

For disposal to watercourse, consent from the Environmental Regulating Authorities (the Environment Agency in the UK) will be necessary.

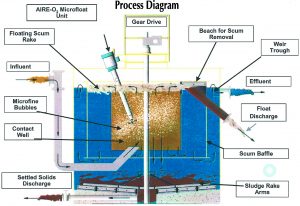

KEE Microfloat Unit Interior working of the Microfloat System

The full treatment options could include anaerobic fixed film technology. This is particularly suitable for high strength wastewater requiring initial partial treatment prior to sewer disposal or further aerobic treatment to produce effluent suitable for direct discharge to a watercourse. The aerobic process could include:

- Suspended Growth Activated Sludge Process options through Extended Aeration, Sequencing Batch Reactor (SBR) or Oxidation Ditch.

- Fixed Film Process through Rotating Biological Contactors (RBC), Submerged Aerated Filter (SAF).

Choosing the Treatment Option

The most suitable process selection would depend on many factors such as:

- Initial Mechanical/Electrical Capital Cost.

- Installation Cost.

- Operating Cost including on-site attendance/labour costs, energy costs, consumables and plant operation complexities. Disposal costs of physically separated pollutants e.g. FOG, TSS and sludge in case of full Biological treatment plant.

- Servicing, Spares & Maintenance Cost.

- Space and Land requirements for location of the on-site treatment plant.

All the above factors should be taken into account and a discounted cash flow calculated on a 10, 15 or a 20-year replacement cycle. This should be weighed against the cost of disposal to sewer or partial treatment followed by disposal to sewer. When evaluating the disposal costs to public sewer, it is necessary to liaise with the authorities or provider of the central wastewater treatment plant, to establish initial capital cost contribution expected and the potential annual costs associated with sewer discharge over the next 10,15 or 20 years. Armed with all this financial data, the overall cost of various disposal options should be evaluated and the financial disposal option chosen justified on a payback period or the net discounted cash flow, or the simple approach of evaluating the cost of disposing a unit volume (say 1 m3) of effluent.

With so many factors to consider, such as type of treatment, if any, the process selection for partial or full on-site treatment and cost analysis to justify the most appropriate option for disposal of the effluent, it may be beneficial to use the services of a professional. An experienced independent consultant with a wide knowledge of industrial wastewater treatment processes would be the obvious choice. Some Companies do offer a wide spectrum of process options and have the necessary experience to offer turnkey solutions using the most optimised process. Such companies may have a bias towards their own technology and process if they have a limited range of process options to offer. All this should be balanced against their ability to provide project management, process design, site civil work, mechanical/electrical erection, commissioning and more importantly on-site operation with process warranties.

The KEE Group Companies, KEE Process Limited and KEE Services Limited can offer such an option. Their technologies include physio-chemical processes (Dispersed Air Floatation, simple gravity solids and grease separators), Anaerobic Reactors (for high strength wastewaters), Fixed Film (RBC and SAF) Reactors and Suspended Growth Reactors (Activated Sludge Processes such as Extended Aeration, SBR, Oxidation Ditch, Extended Aeration followed by Ultra fine Filtration), and on-site operation of the treatment plant. KEE also have a team of experienced process engineers and project engineers capable of delivering the necessary turnkey solution to suit most customers. KEE Services offer on-site plant operation with out-of-hours emergency backup through a 24hrs manned Call Centre.

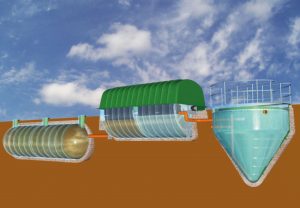

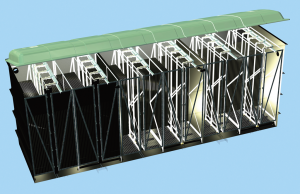

RBC Modular System

Photographs showing SAF, RBC, & SBR plants below:

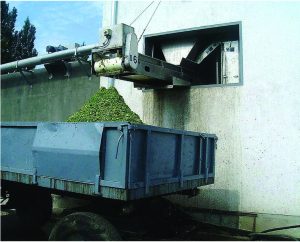

Vegetable processing wastewater screening prior to being treated in a multi-stage Submerged Aerated Filter Plant.

For more information on KEE’s latest NuDisc® RBC, please visit our website or call KEE Process on: 01296 634500

KEE Dispersed Air Flotation Systems (DAF)

Dispersed Air Flotation Systems

KEE Microfloat® Dispersed Air Floatation Technology – for pre-treatment of industrial and food processing wastewater to reduce FOG, BOD, COD & SS. The KEE Microfloat® system produces extremely fine bubbles (10µm to 50µm air bubbles without the use of a high-pressure pump, pressure vessel and venturi) into the water to float the light fractions.

KEE Wastewater Treatment Systems can be configured for BOD removal and/or nitrification and/or de-nitrification and can include a built-in or modular physical-biological tertiary filter. UV disinfection can also be included into the packaged plant to enable non-portable water re-use.

KEE PROCESS LIMITED and KEE SERVICES LIMITED

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.

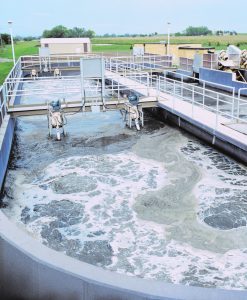

KEE Surface Mounted Fine Bubble Aeration Systems

Surface Mounted Fine-Bubble-Aeration Systems

KEE Triton Aerator/Mixer – The KEE Triton is an energy efficient, dual mode mixer/aerator processor that is capable of nitrification and de-nitrification in one unit. With two propellers and a regenerative blower, the Triton is able to operate either as an anoxic mixer or an aerator/mixer for basins up to 10m deep. The Triton can introduce vital mixing, supplemental aeration or aeration system upgrade to revitalise existing activated sludge treatment plants configured as extended aeration system in circular or rectangular tanks or oxidation ditch configuration to improve plant performance or increase capacity or save energy. Aeration system upgrade does not require plant decommissioning.

KEE Wastewater Treatment Systems can be configured for BOD removal and/or nitrification and/or de-nitrification and can include a built-in or modular physical-biological tertiary filter. UV disinfection can also be included into the packaged plant to enable non-portable water re-use.

KEE PROCESS LIMITED and KEE SERVICES LIMITED

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.

KEE Submerged Aerated Filters (SAF)

Submerged Aerated Filters (SAF)

Modular packaged Single Piece EnviroSAF treatment systems – The KEE EnviroSAF (Submerged Aerated Filter Reactor) for aerobic biological treatment as a single piece compact or modular system. The SAF plants are available as factory built units or on-site erected systems in concrete or glass lined steel panel tanks.

KEE Wastewater Treatment Systems can be configured for BOD removal and/or nitrification and/or de-nitrification and can include a built-in or modular physical-biological tertiary filter. UV disinfection can also be included into the packaged plant to enable non-portable water re-use.

KEE PROCESS LIMITED and KEE SERVICES LIMITED – are BSI Certified Companies (IMS, QMS, OHS & EMS) offering domestic and industrial wastewater treatment solutions using RBC, SAF, MBBR, IFAS, Activated Sludge Process Options (Extended Aeration, SBR, Oxidation Ditch) and enhanced Customer Support by providing on-site service, maintenance and lifetime operation of the KEE Treatment Systems and/or those supplied by others. Their expertise in design, manufacture, servicing, maintenance and operation of equipment for all types of wastewater treatment plants is backed by over 60 years’ experience and over 350,000 installations worldwide.

KEE Triton® UPGRADES EXISTING ACTIVATED SLUDGE TREATMENT PLANT AERATION SYSTEM

The wastewater treatment plant at the village of Keith in Aberdeenshire treats municipal wastewater from the village and effluent from a famous branded Whisky Distillery nearby.

The overall process on site includes inlet works with a grit chamber and screen for municipal wastewater. After this preliminary treatment, the municipal wastewater stream is mixed with the Distillery effluent and is processed through the first-stage high-rate biofilter tower. The effluent from the biofilter tower is then processed through radial flow-scraped primary settlement tanks and the settled effluent is discharged into a two-stage activated sludge basin consisting of two tanks of 7.92m x 7.92m x 4.65m deep (water depth 3.65m). The mixed liquor from the activated sludge plant is discharged through to three radial flow-scraped final settlement tanks and the settled effluent is discharged to a watercourse. The settled sludge is returned (RAS) to the activated sludge basin with excess sent to sludge storage. Finally, supernatant from the sludge storage tank is returned to the feed for the high rate filter tower.

The aeration system for the activated sludge basin consists of two surface-mounted aerators driven by a 20kW common-geared motor through a propshaft delivering approximately 30kg/hour of dissolved oxygen.

EXISTING AERATION SYSTEM – ONLY ONE SURFACE AERATOR OPERATING

The total BOD load to the plant from municipal and industrial sources is 570 kg/day and approximately 285kg of this is reduced through the high rate biofilter and the remaining 285kg/day is required to be treated through the activated sludge plant. The aeration tank capacity is 230m3 each and is normally operated at MLSS concentration of approximately 2000mg/l. One of the surface aerators in the existing aeration system had failed and a temporary venturi aeration system was installed to assist in oxygen supply.

KEE were requested to visit the site, analyse the situation and evaluate the process requirements to make a proposal to upgrade the aeration system. The factors to be taken into account included the need to upgrade the aeration system whilst the plant continued to operate (without decommissioning the plant) and to ensure that the new aeration device produced less than 60dB noise. KEE evaluated the existing process parameters and concluded that the plant could be operated at a higher MLSS concentration of up to 4000 mg/l at a substrate loading rate of 0.15g BOD/g MLSS. The estimated dissolved oxygen demand on this basis would be approximately 33kg/hour.

KEE proposed to install four 5.6kW dual mode Triton processors to provide complete mixing of both the aeration basins and to supply up to 40kg/hour of dissolved oxygen. The Triton dual mode processor is an efficient aeration device which provides total (horizontal and vertical) mixing of the whole basin. It can be mounted from a wall or a bridge or can be supported from floats. The Triton can mix up to a depth of 10m and therefore is also ideal for upgrading existing aeration systems for total replacement or supplemental aeration. The Triton uses a low-power regenerative blower for air supply and a direct-coupled electric motor to generate a plume of fine bubble aeration which is able to penetrate through to the bottom of the tank. This air/water mixer provides a long retention period for air bubbles and the resulting high efficiency oxygen transfer into the mixed liquor. By EPA definition the Triton is a fine bubble aerator.

KEE TRITON® AERATION IN OPERATION

The four Tritons were mounted from the side walls of the existing tanks and, once all the installation work was completed over two days, the electrical cabling was finalised. The blowers supplying air into the Triton were controlled through D.O. probes located in the aeration basin. Once all the electro mechanical work was complete the Tritons were switched on and the old aeration system switched off. The plant aeration system upgrade was achieved in less than one week’s time on site and without any downtime on the existing treatment process. There was no need to hire temporary plants to relieve activated sludge plant. Apart from large savings in capital and operating costs, the biggest benefit was that all the logistics and space problems associated with installing a temporary plant were avoided. The noise emitted by the new aeration system is much lower than specified and definitely lower than the previous system. The process performance of the plant has improved and the plant is able to meet its specified process objectives and has continued to do so for over twelve months.

For more information visit the KEE website.

THE KEE GROUP – WHO AND WHAT ARE THEY?

ENVIRONMENTAL ISSUES affect us all equally and most of us have a heightened awareness of the environmental impact on our planet. All of us need stable climate weather patterns, clean air and clean water for survival and we at KEE play our role in securing the cleanliness of our water sources.

KEE GROUP, comprising of KEE Process Limited and KEE Services Limited is a privately-owned British company which, for the past 60 years, has been at the forefront of providing affordable solutions for the treatment of wastewater and its discharge into a watercourse or the aquafer.

We all take for granted a clean water supply but the treated wastewater discharged into the environment, in almost all cases, does become a source for that clean water supply. Consequently over many years, quality requirements for discharge of treated effluent to watercourses have gradually been tightened up and at present these quality requirements do not only relate to reduction of oxygen demand and suspended solids but also include nutrient removal such as total nitrogen and phosphorus. Behind the scenes at KEE, we have been busy making sure that we continue to rise to the challenge of the stringent requirements for discharge of treated effluent from Municipal and Industrial wastewater treatment systems.

To support this mission, KEE has patented and introduced a large range of technologies and hardware to provide systems for treating small and large flows. The small flows are treated using KEE NuDisc® single-piece packaged plants, which are designed and engineered to provide value for money and are configured to operate with minimum day-to-day intervention. In addition to these single piece KEE NuDisc® packaged plants, there is the modular system arrangement, based on various technologies such as RBC, SAF and Activated Sludge plants. These single piece and modular packaged plants are versatile in their application and are able to provide nutrient (total nitrogen and phosphorus) reduction in the packaged plant configuration.

KEE also provides and supplies solutions for larger flows, which may involve construction of a plant from modular components and hardware, or a totally on-site built system. KEE has all the technology options at its disposal and is therefore able to process-engineer the optimum solution for the application, taking into account the customer’s needs and the site requirements. To facilitate this, KEE provides the services of its Process Engineers to evaluate the site requirements and the treatment objectives. KEE wastewater treatment technologies include Submerged Aerated Filters (SAF), Rotating Biological Contactors (RBC), Extended Aeration Activated Sludge Treatment Plant, Sequencing Batch Reactor Activated Sludge Plants, Oxidation Ditch, Ultra-Fine Filtration Modules, Dispersed Air Flotation (DAF and Microfloat) and Anaerobic Reactor for treatment of high-strength industrial wastewaters. The suitability of any one, or a combination of these technologies and unit operations, will be assessed to arrive at the most optimised solutions.

KEE has introduced various features in the hardware offering the above technologies and these include:

- Patented Managed Flow features in the system enabling hydraulic and organic attenuation of loads.

- Removable fine bubble membrane diffusers in SAF Systems without the need to remove the media or empty the tank.

- Highly efficient and cost effective dispersed air Microfloat® System for removal of fat, oil, grease, suspended solids, BOD and COD from industrial wastewater discharge.

Introduction of high-efficiency surface-mounted dual mode processor designed to provide efficient mixing and fine bubble aeration of deep basin activated sludge systems.

A good and well-executed engineered solution for treatment of wastewater is only part of the total ongoing requirement for our clients. To complete the package, KEE also offers its clients the basic service and maintenance of hardware and equipment, or can take over the total operation and maintenance of the plant on behalf of the client. The objective for KEE is to provide their customers with the lowest lifetime cost solution and KEE rises to the challenge by offering to operate the plant at a fixed price. This gives the client complete peace of mind. KEE also offers to operate and maintain plants supplied by other manufacturers after an initial survey and evaluation of the system already installed.

The Literature site includes a complete set of KEE literature and Press information on all their technology and services offered, including KEE NuDisc®, KEE EnviroSAF, KEE Microfloat® Dispersed Air Flotation System and the Triton® Dual Mode Processor for aeration and mixing of activated sludge in conventional and extended aeration plants and oxidation ditches.

To see the capabilities of the KEE Group of companies please visit the KEE Group website.