Click on images below to view leaflets.

Tag Archives: KEE Services upgrading a wastewater treatment plant

Check out the KEE profile on the UK Projects online portal

Update of expired sewage treatment facility with a KEE Rotating Biological Contactor prevents pollution to River Dene

KEE RBC replacing expired Sewage Treatment Facility under Section 101a of the Water Industry Act

The picturesque village of Walton is located within the heart of Warwickshire adjacent to the River Dene. The existing privately owned sewage treatment facility located on the bank of the River Dene was life expired and would often flood, resulting in pollution to the river. An application was made to Severn Trent under Section 101a of the Water Industry Act to provide a first-time sewage connection for all 20 properties in Walton village with a population of approximately 70 people. Due to the remote location of the village, a connection onto the existing Severn Trent sewer network, either gravity sewer or a pumped solution, was not deemed feasible. Therefore, the proposal was for the installation of a new rotating biological contactor (RBC) to replace the existing treatment facility.

Full project case study, click here

For KEE RBC information

click here

For more information on KEE technology and services please visit our website or call 01296 634500

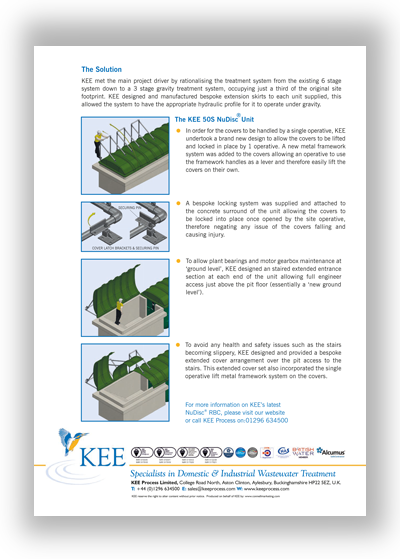

KEE design and manufacture a gravity NuDisc® wastewater treatment plant to replace a decades old treatment system.

KEE’s solution was to provide a gravity system which incorporated all the clients wishes for ongoing operation and maintenance with enhanced Health and Safety features all within a smaller footprint than the existing treatment works.

Marc Goldby – Head of Home Investment at Bromford commented, “KEE have been an integral partner in Bromford’s wastewater investment programme, consistently providing a first class service as highlighted by the project at Woodmancote, meeting all of our requirements and one both we and our customers can be confident in for years ahead.”

For more information on KEE technology and services please visit our website or call 01296 634500

Why you should choose KEE in 2021

Our specialist knowledge and expertise is derived from over 65 years’ experience in the development, design, manufacture, servicing, maintenance and operation of wastewater treatment systems and equipment. Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Contact us to discuss how we can help you on:

01296 634500, or visit our

website – www.keeservices.com

Flooding Hazards to Wastewater Treatment Plants

Flooding Hazards to

Wastewater Treatment Plants

Flooding and saturated ground cause significant problems for sewage treatment plants and as the UK receives more frequent severe rainfall events, the issue of pollution from sewage treatment plants and septic tanks is an ever increasing threat.

What is the effect of a sewage treatment plant flooding?

The effect of a sewage treatment plant flooding is not limited to contamination. Nearly all sewage treatment plants have some form of motor or compressor which is responsible for driving the treatment process. If these flood, then they will need to be replaced once the flood waters recede.

The most common Septic tank problem that arises due to flooding is that saturated ground cannot absorb any additional water and hence many sites with drainage fields suffer during prolonged periods of rain because the sewage system backs up.

To view Do’s and Don’ts to caring for your sewage treatment plant, click HERE.

Alternatively Contact KEE to discuss service contracts available or arrange a service engineer to repair/service your wastewater treatment system or evaluate potential problems before they happen.

Call: 01296 634500,

visit our website – www.keeservices.com

or email – service@keeservices.com

At KEE we are ‘open for business’

The KEE Group provide solutions to the Wastewater Treatment Industry for all domestic, commercial and industrial applications. CLICK HERE

- KEE are committed to providing total customized solutions for the treatment of wastewater and have the most innovative systems to treat every situation.

- KEE leads the country in the supply, maintenance and operation of wastewater treatment systems and can provide you with the best solution.

- KEE systems are also available for hire.

KEE Services comprises a complete range of options, from simple servicing and repairs through to full service, maintenance and plant operation, including:

- On-Site Plant Operation

- Facilities Management

- Emergency Service

- Planned Maintenance

- Breakdowns

- Equipment Refurbishment

- Spares

- BioGuard™ Grease Digester

- Ancillary Products

KEE wastewater technology provide total solutions for the treatment of wastewater:

- Process Engineering

- Project Management and Turnkey Projects

- Pumping Equipment

- Dispersed Air Floatation (DAF)

- Anaerobic treatment for industrial wastewater

- Sequencing Batch Reactor

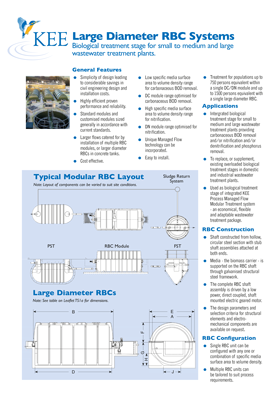

- NuDisc™ and Packaged RBC Systems

- Submerged Aerated Filters (SAF)

- Oxidation Ditch

- Installation and Commissioning

- Nutrient Removal

For full information on our KEE services and process technology, visit our WEBSITE.

KEE Reminder – It’s All Change in January 2020

What do the new Septic Tank Regulations mean to you?

Back in November 2017, we wrote a blog advising all our customers of the change in Septic Tank Regulations which come into effect on the 1st January 2020. If you have a Septic Tank at home or at work and it’s discharging into a river, stream or surface water, we recommend that you take action now and review replacing it with a Wastewater Treatment Plant to meet the new EA regulations coming into force on the 1st January 2020.

Discharges from septic tanks directly to surface water will no longer be allowed under the general binding rules.

To help guide you on the new regulations, please read our last blog on the subject here and the click on the link to the current Gov.UK webpage on the subject here

KEE Process & KEE Services specialise in Wastewater Treatment Plants so if the changes in regulations apply to you then please do give us a call on 01296 634500 as soon as possible so we can help guide you through the process and advise you on the best approach to meet your requirements and EA regulations.

‘Out with the Old and in with the NuDisc’ at RSPB Headquarters, Bedfordshire

This month the RSPB have a shiny new KEE Wastewater Treatment Plant installed. This replacement KEE NuDisc® 20HR model and Twin Pump Station replaces their old G7 BioDisc Unit and Pump Station. The old plant was no longer suitable for their headquarters in Sandy due to the increasing staff numbers based on site and visitors attending the nature reserve.

The KEE NuDisc 20HR and Twin Pump Station that replaces the old BioDisc

The old G7 BioDisc that’s no longer fit for purpose

For more information on KEE’s Wastewater Treatment Plants, or potential existing plant refurbishments or upgrades, please visit our KEE Process website or call us on 01296 634500

Private Residential Golfing Community in New York State Selects KEE Process Managed Flow® Wastewater Treatment Process

Bristol Harbour is a private residential golfing community in the Western Finger Lakes of New York State, USA.

Having experienced ongoing problems with their existing wastewater treatment plant, the community approached KEE Process Limited’s North American partner, Waste Water Solutions International Inc., for help.

After suffering regular mechanical failures, deviations in effluent performance and high operating costs, the community recognised the need to upgrade their aeration plant. The new system would also need to cope with the planned expansion of the development and meet the State Law’s stringent treatment requirements.

The KEE Process Managed Flow® Process was selected because of its ability to continually produce high quality effluent and its low operator costs and maintenance. The system was also ideal for the site’s limited space and environmentally sensitive location.

To provide flexibility two streams were installed. The technology chosen included:

- A balancing tank

- KEE Process Managed Flow Rotating Biological Contactor (RBC) – Model DN-19-S

- KEE Process Final Settlement Tank (Model ST9) with automatic pump assisted sludge return system and gravity sand filter with backwash capability.

This technology was designed and specified to provide for the current and future expansion of the community.

The KEE Process Managed Flow RBC Model DN-19-S and a KEE Process Final Settlement Tank Model ST9 with automatic pump assisted sludge return system and gravity sand filter with backwash capability installed at the Bristol Harbour private residential golfing community in the Western Finger Lakes of New York State, USA.