Click on images below to view leaflets.

Category Archives: KEE NuDisc Technology

Check out the KEE profile on the UK Projects online portal

Update of expired sewage treatment facility with a KEE Rotating Biological Contactor prevents pollution to River Dene

KEE RBC replacing expired Sewage Treatment Facility under Section 101a of the Water Industry Act

The picturesque village of Walton is located within the heart of Warwickshire adjacent to the River Dene. The existing privately owned sewage treatment facility located on the bank of the River Dene was life expired and would often flood, resulting in pollution to the river. An application was made to Severn Trent under Section 101a of the Water Industry Act to provide a first-time sewage connection for all 20 properties in Walton village with a population of approximately 70 people. Due to the remote location of the village, a connection onto the existing Severn Trent sewer network, either gravity sewer or a pumped solution, was not deemed feasible. Therefore, the proposal was for the installation of a new rotating biological contactor (RBC) to replace the existing treatment facility.

Full project case study, click here

For KEE RBC information

click here

For more information on KEE technology and services please visit our website or call 01296 634500

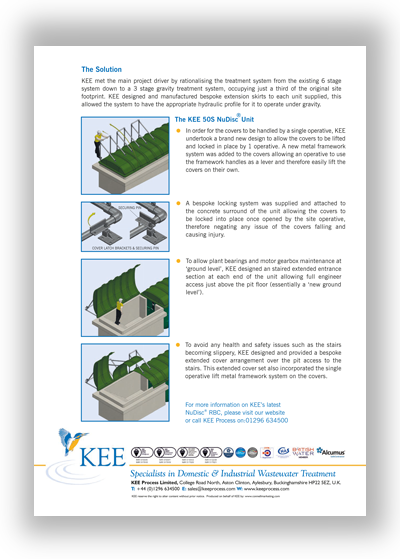

KEE design and manufacture a gravity NuDisc® wastewater treatment plant to replace a decades old treatment system.

KEE’s solution was to provide a gravity system which incorporated all the clients wishes for ongoing operation and maintenance with enhanced Health and Safety features all within a smaller footprint than the existing treatment works.

Marc Goldby – Head of Home Investment at Bromford commented, “KEE have been an integral partner in Bromford’s wastewater investment programme, consistently providing a first class service as highlighted by the project at Woodmancote, meeting all of our requirements and one both we and our customers can be confident in for years ahead.”

For more information on KEE technology and services please visit our website or call 01296 634500

Why you should choose KEE in 2021

Our specialist knowledge and expertise is derived from over 65 years’ experience in the development, design, manufacture, servicing, maintenance and operation of wastewater treatment systems and equipment. Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Contact us to discuss how we can help you on:

01296 634500, or visit our

website – www.keeservices.com

Guide for users of Packaged Wastewater Treatment Plants codes of practice has been updated

British Water are in the process of updating their

off-mains sewerage infrastructure codes of practice

https://www.britishwater.co.uk/Publications/codes-of-practice.aspx

CLICK HERE: Guide for users of Packaged Wastewater Treatment Plants.

(Updated June 2020)

For full information on our KEE services and process technology, visit our WEBSITE

At KEE we are ‘open for business’

The KEE Group provide solutions to the Wastewater Treatment Industry for all domestic, commercial and industrial applications. CLICK HERE

- KEE are committed to providing total customized solutions for the treatment of wastewater and have the most innovative systems to treat every situation.

- KEE leads the country in the supply, maintenance and operation of wastewater treatment systems and can provide you with the best solution.

- KEE systems are also available for hire.

KEE Services comprises a complete range of options, from simple servicing and repairs through to full service, maintenance and plant operation, including:

- On-Site Plant Operation

- Facilities Management

- Emergency Service

- Planned Maintenance

- Breakdowns

- Equipment Refurbishment

- Spares

- BioGuard™ Grease Digester

- Ancillary Products

KEE wastewater technology provide total solutions for the treatment of wastewater:

- Process Engineering

- Project Management and Turnkey Projects

- Pumping Equipment

- Dispersed Air Floatation (DAF)

- Anaerobic treatment for industrial wastewater

- Sequencing Batch Reactor

- NuDisc™ and Packaged RBC Systems

- Submerged Aerated Filters (SAF)

- Oxidation Ditch

- Installation and Commissioning

- Nutrient Removal

For full information on our KEE services and process technology, visit our WEBSITE.

Spare a thought for your Sewage Treatment Plant this Christmas

Spare a thought for your

Sewage Treatment Plant this Christmas

With the festive season upon us, guests arriving and the celebrations in full swing, please do keep in mind what you and any visitors are pouring or flushing down your drainage system into your Sewage Treatment Plant.

Do’s

- Follow manufacturers’ recommended doses for your water type when using household cleaning products. Soft water requires far less detergent concentration than hard water.

- Try to use cleaning products little and often so your treatment plant is not overloaded.

- Use liquids (not powders) in washing machines and dishwashers. Powders re-coagulate into clumps and can cause blockages.

- Try to spread your clothes washing throughout the week.

- Stick to the same washing, dishwasher and other cleaning products as the bacteria will work more efficiently with products it is used to treating.

- Think before you put anything down the sink, toilet or drains.

- Desludge your plant when required. Click HERE to view our one page KEE EXPERT guide on proficient desludging and how regularly your unit should be desludged.

- Ensure only toilet paper is flushed down the toilet and used in normal quantities.

- Leave your plant switched on while you are away or on holiday. Switching off your plant can cause damage to the motor and moving parts as well as kill the biomass.

- Compost all your organic food waste or use your local council bio-degradable waste recycling service (where applicable) to dispose of organic waste. Do not flush organic waste down the sink or drain.

Don’ts

- Don’t put sanitary towels, tampons, cotton wool or cotton wool buds, incontinence pads or any baby, cleaning or facial wipes down the toilet.

- Don’t flush rubber products or other non-biodegradable products down the toilet.

- Don’t pour fat, grease or cooking oil down the sink or drains. Fats suffocate the bacteria and inhibit the biological process. Everyday products such as milk, wine or beer increase the organic load and should also not be disposed of through the wastewater system.

- Don’t use neat disinfectant or bleach. KEE recommends that these products are only used at the minimum concentration possible, as they can restrict the biomass growth within the plant.

- Don’t tip medicine, mouth wash or any chemicals such as photographic fluid or garden products (e.g. Insecticides, weed killers and fungicides) down the drains as they will damage the biological treatment process.

- Don’t pour DIY products (e.g. paint, thinners, turpentine and white spirit etc.) or car fluids such as engine oil, anti-freeze, brake fluid etc. down the drains.

- Don’t allow rainwater, groundwater or large volumes of water (such as those from a swimming pool or Jacuzzi) into the plant. Chlorine kills the bacteria and the excessive water will increase the flow rate through the plant, not allowing sufficient treatment time.

- Don’t fit a waste disposal unit under your kitchen sink. Disposing of organic matter through the treatment system increases the organic load, creating bacterial overgrowth which will inhibit the treatment process. Only use a waste disposal unit if your plant is specifically designed to accept higher organic loads.

Click the image to download the leaflet.

For more information visit our website or call

KEE Services on:

01296 634500

Don’t want to pay for a new treatment plant – why not refurbish your old one?

KEE Process and KEE Services Limited have been commissioned to refurbish and update countless old and tired treatment plants. The example shown below is of a unit located in a small Welsh Village. The ageing plant was proving unreliable and not performing efficiently so KEE designed and built a KEE NuDisc® to replace and update the old treatment plant.

KEE’s upgrade solution was – KEE NuDisc® Technology.

Often the structural housing of a wastewater plant can be re-used, meaning the internal components are replaced with brand new factory built KEE systems, incorporating the latest concepts in mechanical, structural and process engineering.

Refurbishments of this kind extend the life of the plant by another 20 years, drastically reducing the overall lifetime cost when compared to installing a brand new plant.

KEE’s Service technicians complete a full refurbishment suitability survey to assess the compatibility of each plant for an upgrade. This is applicable to all manufacturer makes of wastewater treatment plants and not just those designed, and produced by KEE. Water Authority sites have proved popular with refurbishments, reducing Water Authority spending and providing brand new refurbished treatment plants which are fully compliant to the relevant Authority specification.

Refurbishments remove the costly civil work elements associated with complete plant replacement.

Utilising current process equipment can often increase the treatment capabilities of the existing system, therefore making the refurbished plant fit-for-purpose for increased flows and loads, a problem which often occurs with old systems as more influent is added to it over their working life.

Following refurbishment KEE can continue to service, maintain and monitor the condition of the plant to keep it in good working order and performing efficiently.

Why Refurbish?

- Minimises waste by only replacing the parts of the plant that need replacing.

- Greatly reduces the volume and complexity of site works.

- Less noise and general disturbance on site.

- Minimises plant ‘downtime’. A refurbishment is generally quicker to complete than a new installation.

- Incorporates the latest process design features and efficiencies such as KEE’s ‘managed flow’ system to protect the environment and meet wastewater consents and legislation.

- Reduce or eliminate the need to find an alternative location for a new plant.

- Extends plant lifespan by 20 years, at a fraction of the total cost of a new plant.

For more information on plant upgrades, refurbishments or new wastewater treatment systems, please visit our website or contact us on: 01296 634500

‘Out with the Old and in with the NuDisc’ at RSPB Headquarters, Bedfordshire

This month the RSPB have a shiny new KEE Wastewater Treatment Plant installed. This replacement KEE NuDisc® 20HR model and Twin Pump Station replaces their old G7 BioDisc Unit and Pump Station. The old plant was no longer suitable for their headquarters in Sandy due to the increasing staff numbers based on site and visitors attending the nature reserve.

The KEE NuDisc 20HR and Twin Pump Station that replaces the old BioDisc

The old G7 BioDisc that’s no longer fit for purpose

For more information on KEE’s Wastewater Treatment Plants, or potential existing plant refurbishments or upgrades, please visit our KEE Process website or call us on 01296 634500