KEE was formed as a family run business back in 1955. Although the industry has changed significantly since then, KEE’s ‘family’ company culture continues to focus on ethical business values and an integrity and commitment to delivering high quality products and services to its customers.

KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the development, design, manufacture, installation, servicing, maintenance, refurbishment and operation of wastewater treatment systems and equipment.

Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Many of our customers today have been working with KEE for over 30 years which is a testament to the trust, loyalty and value our customers have in us as a supplier.

Operation, Service & Maintenance of Wastewater Equipment

- KEE Engineers have decades of experience in maintaining of all types of sewage treatment equipment and pumping stations, providing peace of mind that your equipment is in safe hands.

- KEE operate to the highest standards of practice. We are BSI ISO 9001 Quality Management accredited in the commissioning, servicing, maintaining and operating of domestic and industrial wastewater treatment systems. Our Service Technicians are DBS checked and British Water accredited.

- KEE believes in creating the very best products to protect the environment. Our KEE designers undertake on-going research and development to continue delivering process and cost efficiencies using the very latest advancements in design technology. For example, this year we launched a new Tertiary Filter and UV light disinfection system for the KEE NuDisc-R® which offers superior wastewater quality discharge.

- KEE Engineers only fit genuine KEE approved parts, selected for their quality, durability and value for money.

- KEE’s annual ‘Maintenance Service’ includes a comprehensive 127 point checklist report, providing a full analysis of the electrical, mechanical and operational condition and performance of your plant.

- KEE’s Service Managers and Engineers offer professional advice on looking after your plant, controlling maintenance costs and avoiding expensive damage to your equipment.

- KEE design and undertake bespoke and standard plant refurbishments and upgrades, meeting the changing needs of our customers and the environment.

An ‘End-to-End’ Service Solution

KEE Services offer a range of maintenance, operation and breakdown services for all types of treatment plant and pumping equipment, from all manufacturers.

- Annual Plant Electrical & Mechanical Service and Maintenance Assessment

- Sewage and Wastewater Plant Management and Operation

- Planned Preventative Maintenance

- Nationwide 24hr Emergency Call-Out

- Plant and Equipment Breakdown Repair

- UKAS Accredited Laboratory Effluent & Water Sampling

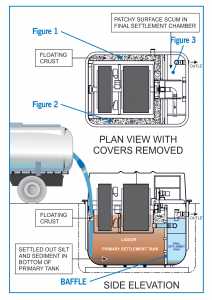

- Tankering and Jetting Advice, Scheduling and Operational ‘Supervision’ Service

- New Plant Supply, Installation and Commissioning

- Forecourt Services

- KEE Approved Spares and Replacement Parts

- Commercial and Domestic Sewage Systems

- Grease Management via Dosing/Physical Removal

- Domestic and Industrial Plant Hire and Rental

KEE know that professional maintenance will extend the life of your plant and minimise the risk of serious damage and breach of environmental consents.

Our nationwide team of directly employed regionally based KEE engineers are trusted by over 6,000 customers.

So . . . whether you have a single, or multi-site operation across the UK, KEE can design and deliver a tailored service solution to meet your requirements and liaise with the Environment Agency on your behalf if required.

For more information, please call Julie or Natasha on

01296 634500 or email us at sales@keeservices.com