Developed by KEE the NuDisc© 5000 HD RBC Sewage Plant and Treatment Centre – a new single-piece factory-built plant to add to their range to meet Severn Trent Water’s extremely stringent requirements.

Situated in the heart of the Peak District, the village of Hassop in north Derbyshire lies approximately 11 miles east of Chesterfield and 2 miles to the north of Bakewell, and is within the Severn Trent Water’s catchment. The properties subject to the Section 101a application were served by a village drain. This received flows from septic tank high level overflows and discharged to a local un-named watercourse. Local ground conditions were unsuitable for soakaways. Hassop Estate applied, under Section 101a of the Water Industry Act 1991 in December 2007, for a public sewerage system to be provided.

In 2010 STW accepted the need to lay new sewers and treatment system. The new wastewater treatment works was required to treat flow from a population equivalent of 210, and the consent to discharge for this site required that the BOD < 20mg/l, SS < 30mg/l and NH4-N < 5mg/l.

Project background and cost considerations

The construction of the Hassop WwTW involved the laying of approximately 1600m of foul sewer, an intermediate pumping station and a new RBC Unit to serve the Village. The work was undertaken by NMCNomenca as the Tier 1 Framework Partner and as part of S101A Scheme for Severn Trent Water Ltd.

NMCNomenca’s scope of works was for the detailed design, construction and supervision of the whole project from start to finish. NMCNomenca were also in control of the site until handed back to Severn Trent Water Ltd after commissioning and testing.

The project for capital delivery had to take into account CAPEX and OPEX costs to determine lifetime costs for the project over 20 years. This included the capital cost of delivering the project; design, manufacture, delivery and commissioning of the process plant and all site-related costs including provisions for on-site health & safety, environment and personal welfare for site operatives. The second part of the costs related to operational costs and included cost of energy, consumables, spares, labour and process-related costs such as desludging. The overall objective for the consortium is to minimise lifetime costs without compromising any aspects of the project delivery including site work.

Consent standards

The site at Hassop required to treat wastewater from a population equivalent of 210 with design DWF of 32m3/d, FFT of 173m3/d, BOD load of 12.6kg/d, SS of 15.75kg/d and NH4-N of 1.68kg/d. The consent to discharge for this site required that the BOD< 20mg/l, SS < 30mg/l and NH4-N < 5mg/l.

Such consent standards from the Environment Agency are common for wastewater discharge to a watercourse, although for a small works with such a large variation in design flows during dry and wet weather, this does present a challenge to the designers to ensure that the plant performs to requirements under all these conditions throughout the year.

Process plant selection

KEE Process has, over the last 60 years, developed a range of plants to treat wastewater from municipal and industrial sources to similar and more stringent standards where the BOD values could be less than 5mg/l, SS less than 10mg/l, ammoniacal nitrogen less than 1mg/l, phosphorus less than 1mg/l and total nitrogen less than 15mg/l. The range from KEE includes small packaged systems for small flows, modular packaged units for larger flows and in situ constructed plants for populations larger than 5,000 PE.

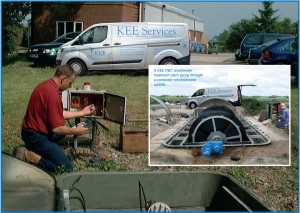

For the site at Hassop, the largest single-piece factory-built plant available at the time in KEE’s range was not adequate to deal with the flows, so KEE developed a new single-piece factory-built plant to add to their range. The single-piece plant would be factory built and would take into account all the requirements laid out by Severn Trent Water in its specification and the plant would be delivered to site ready to be placed on a pre-prepared concrete slab and backfilled.

The plant would include installation of the remote desludging facilities and internal electrical wiring during the plant construction in the factory. This would, in effect, be a true ‘plug and play’ system with the objective of reducing site-related construction time and costs.

Building a plant in a factory provides a controlled environment and conducive conditions for maintaining quality standards, which are often difficult when the build is undertaken at a construction site under the prevailing conditions, which may include rain, snow, low temperatures and hazardous operating environment.

In addition, a factory-built plant would enable the duration of construction on site to be substantially reduced, as the factory-built plant can be backfilled within a day or two of being delivered. This means that the excavation is not left open for long periods and, in turn, this reduces any health and safety risks associated with working on site with deep excavations and in confined spaces. However, this may have a major impact on the project costs when plants are factory built compared to building on site.

NuDisc®

KEE NuDisc® 5000 includes the primary sedimentation stage with sludge storage, RBC for biological treatment and a hopper final clarifier, all housed in a single structural GRP housing and covered with lightweight GRP covers.

The RBC is driven by a 0.75kW geared motor at a slow speed of 1rpm and is designed to comply with all the structural and mechanical requirements stipulated by Severn Trent Water Ltd.

The FST includes a fully automated descumming and desludging system, for removal of scum and sludge at regular hourly intervals back to the primary clarifier.

The primary clarifier includes remote desludging facility and this is carried out at regular intervals of 90 days when 18.9m3 (5000 gls) of sludge is tankered away.

KEE packaged plants also include flow attenuation within the primary settlement chamber, in order to provide process stability with the large fluctuations in design flows.

The manner in which the attenuation system is organised also enables evening out peaks and troughs in organic load and this attenuation is achieved in the first stage of the biological process.

Designed and built at KEE’s factory, the KEE NuDisc® 5000 was delivered on time on a cold snowy day and was placed in an excavation ready to be backfilled all on the same day.

The plant was fully commissioned to receive flows only seven weeks from delivery – a big achievement for all the parties involved including KEE Process, NMCNomenca and the client, Severn Trent Water. All other site related matter including landscaping, electrical control gear, remote telemetry system and landscaping were completed within timescales.

Operational and maintenance requirements

The operational and maintenance requirements are desludging every 90 days, lubrication of bearings required every six months. With a daily energy consumption estimated at 21kWh/d. The OPEX costs for the site are therefore minimised.

Summary

Although KEE Process does not have comparative lifetime costs for this specific project, the costs for similar projects with other water companies have shown 30% reduction in capital costs compared to other technologies with substantial amount of site related construction and equally a large proportion of savings in operating costs resulting from savings in energy consumption and operational labour requirement.

KEE, a BSI Certified Company (IMS, QMS, OHS & EMS) offers domestic and industrial wastewater treatment solutions including lifetime operation and maintenance using RBC, SAF, SBR and Extended Aeration. With 60 years’ experience and over 350,000 installations, KEE have the expertise in design, build and operation of all wastewater treatment plants.

For full information on KEE Technologies and Services visit the KEE Group website: