KEE Process has been working with private companies and public bodies in Ireland for over 40 years.

KEE Process is a major supplier of process engineered treatment systems to local councils and private companies in Northern and southern Ireland. KEE has supplied and installed plants at over 20 sites in Southern and Western Divisions of Water Services, Northern Ireland, for populations ranging from 100PE to 3000PE. The applications vary from simple municipal wastewater treatment plants providing basic treatment to supplying plants designed to produce high quality effluent with less than 3 mg/l of ammoniacal nitrogen and less than 5mg/l BOD and suspended solids.

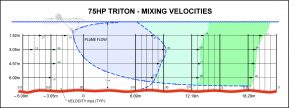

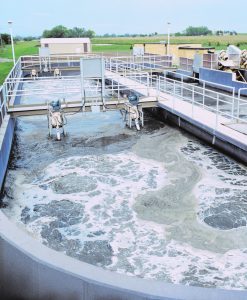

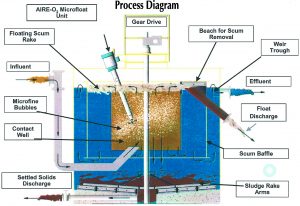

KEE Process has worked with a number of Irish councils to upgrade treatment plants to allow the discharge of highly polluted industrial effluent into their systems. In many cases the requirements are stringent, requiring total nitrogen and phosphorus removal. KEE has a team of experienced process and project engineers capable of delivering solutions that combine simplicity of process design with low lifetime cost. Municipal wastewater treatment plants for small communities can be designed to accommodate and treat industrial discharges as long as these are taken into account at the design stage. However, sudden or intermittent discharge of industrial wastewater would shock load a small treatment plant and cause the municipal treatment plants to become overloaded and malfunction. KEE Process has provided solutions to overcome these problems. KEE has upgraded municipal facilities without upheaval and also overcome the problems by providing partial treatment of industrial discharges at source. This is particularly the case with municipal facilities which become oxygen limited in the activated sludge stage. One solution is to install a versatile dual mode TRITON® processor which provides mixing and/or introduces dissolved oxygen into the mixed liquor. A KEE DISPERSED AIR FLOATATION (DAF) MICROFLOAT® SYSTEM can be used to provide partial on-site treatment for industrial discharges, thereby reducing the load discharged into the sewer and the municipal treatment plant. KEE used its TRITON® Aerator to upgrade an overloaded municipal plant to accommodate loads generated from a distillery and are also in the process of upgrading a dairy plant using TRITON® to overcome oxygen deficiencies and to further introduce biological phosphorus removal in the plant. A KEE DAF system would be installed upstream of the biological process for fat removal.

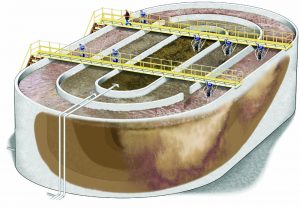

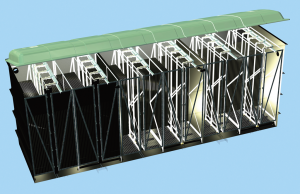

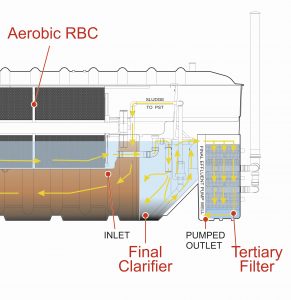

KEE Group technologies include physio-chemical processes such as DAF, simple gravity solids and grease separators, biological processes such as anaerobic reactors (for high strength wastewater), fixed film Reactors (RBC & SAF) and suspended growth reactors (activated sludge processes – extended aeration, oxidation ditch, SBR, and extended aeration followed by Ultra Fine Filtration).

With the introduction of the European Water Framework Directive (WFD) and the need to treat pollution, it goes without saying that the polluter pays. Consequently, industries which discharge large quantities of heavily polluted wastewater into the sewer will have to consider the options for on-site treatment to reduce their costs and the loads on the municipal treatment facilities. The treatment options which they should consider are physical, physical/chemical or biological treatment, or a combination of all or any of these. KEE Process have designed and supplied municipal wastewater treatment plants in Northern Ireland for sites at Kinallen, Fivemiletown, Bergah, Ballinamallard, Fintona, Lisbellaw, Caledon, Lislea and many others. In Ireland many of KEE’s projects have been delivered through partnerships with John Molloy Engineering Ltd (JME), a firm of local M & E contractors who offer total supply and installation packages, with fully comprehensive after sales support. Some of these projects include plants built at the following sites:

- Woodenbridge Hotel, Co. Wicklow.

The Woodenbridge hotel had a wastewater treatment plant that was failing to meet consent and was expensive to maintain and operate. When it decided to build a new 40-bedroom lodge on the Co. Wicklow site, the management decided to build a new plant to treat all the existing flows as well as the flows from the 40-bed expansion. The onerous discharge requirements included reduction of total nitrogen and phosphorus and the plant had to produce final effluent to comply consistently with BOD < 20 mg/l, SS < 30 mg/l, COD < 80 mg/l, NH4-N < 20 mg/l, NO3-N (Nitrate Nitrogen) < 5 mg/l, Phosphate as PO4 < 12 mg/l, FOG (fat, oil and grease) < 20 mg/l and Detergent (MSAS) < 1 mg/l.

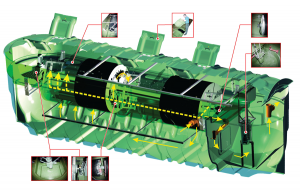

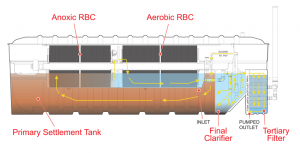

The plant also had to have low operational and maintenance costs. The supplier had to be able to provide a complete service including planned preventative and emergency maintenance, process and operation maintenance as well as effluent sampling. The proposal involved KEE and JME supplying, delivering, installing and commissioning a 60m3 primary settlement tank, a Module DC16 Rotating Biological Contactor and an ST6 hopper bottom GRP final settlement tank. All this equipment was factory built and delivered to the hotel site ready for installation on concrete slabs. The plant was installed and commissioned in 2003. Since then it has operated extremely well mechanically and has delivered excellent process performance. The total electricity costs for the plant are less than EUR 1,000 per annum.

- Muskerry Golf Club.

This was a design and build turnkey contract for JME and KEE who were process partners in the project. The discharge license was direct to the watercourse and specified a BOD < 20 mg/l, SS < 30 mg/l, NH4-N < 20 mg/l and Phosphate as P < 2 mg/l. KEE supplied their compact single piece NuDisc® Model 1200 and JME laid the sewer, outfall and installed the treatment plant with a committee of engineers from the club supervising the entire contract.

- Portmarnock Golf Club.

Portmarnock Golf Club in North County Dublin is one of Ireland’s premier link courses. During the recent refurbishment of the clubhouse, new on-site sewage treatment plant and disposal systems were required. The discharge license specified a BOD < 20 mg/l, SS < 30 mg/l and NH4-N < 10 mg/l, NO3-N (Nitrate Nitrogen) < 15 mg/l, Phosphate as PO4 < 5 mg/l and FOG (fat, oil and grease) < 10 mg/l. KEE Process Ltd and JME designed the process and supplied and installed a single-piece compact packaged plant NuDisc® F13N with inbuilt de-nitrification and phosphate removal stages. The JME contract also included the design and installation of an inlet pumping station and a sub-surface percolation area.

- Kilbride Army Camp.

This was a plant for a military camp with variable flows and high fluctuations in the seasonal loads and an onerous discharge license with BOD < 10 mg/l, SS < 10 mg/l and Phosphate as P < 2 mg/l. KEE supplied its packaged compact single piece NuDisc® Model F13 and JME led the contract on installation and commissioning.

- Cork County Council, Killeagh.

This was an installation for a municipal treatment works for Cork County Council for 1000 PE. The flow to the works are from combined drainage systems with a discharge license for BOD < 20 mg/l and SS < 30 mg/l.

KEE supplied their packaged modular treatment system and JME led the contract for installation and commissioning.

To see the capabilities of the KEE Group of companies please visit the KEE Group website