The KEE NuDisc® Single Piece Packaged Plant and the NEW NuDisc-R® – is an innovative and a truly versatile systems for the effective treatment of wastewater, including Nutrient removal. A new optional feature has been built into the NuDisc Single Packaged Plant to create the NEW KEE NuDisc-R® Packaged Plant System – physical-biological tertiary treatment with water recycling.

Flexible solutions have long been at the heart of our philosophy and we are now pleased to be able to offer one solution to meet every need. Despite being able to handle a variety of flow rates and numerous final effluent types, the KEE NuDisc® technology combines features that actually simplify its operation and maintenance without compromising the results.

From the moment the KEE NuDisc® is installed, low operating and powercost with long design life ensures low life time cost. The KEE NuDisc® provides the assurance that wastewater is being properly handled and the risk of pollution in the local environment is minimised. KEE can provide a fixed price maintenance package to cover for all mechanical and electrical items and the labour costs after the initial warranty periods.

KEE NuDisc®

RBC Single Piece Packaged Wastewater Treatment System

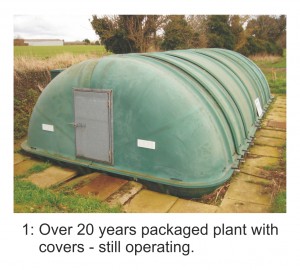

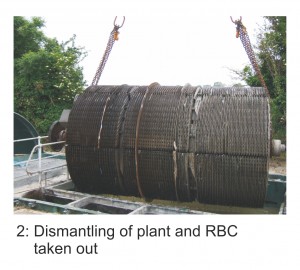

KEE Process Ltd has always been a leader in innovative technology for wastewater treatment. The company offers the versatile NuDisc® Single Piece Packaged Plant for the treatment of wastewater. It can be applied to achieve any one or a combination of requirements, including BOD5 reduction, nitrification, total nitrogen reduction or phosphorous removal. Built on KEE’s own proven technology introduced over 60 years ago, the NuDisc® brings many advanced features specifically aimed at simplifying the operation and maintenance of the plant. Its design provides a structural GRP Tank and internal components designed for a life in excess of 30 years. The mechanical components are selected for 100,000 hours L10 life. The end result is a plant with extremely low lifetime costs.

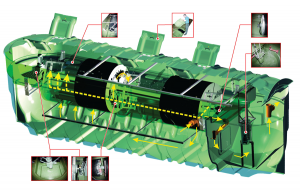

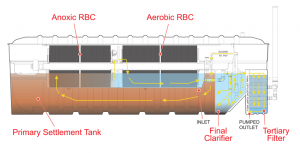

The KEE NuDisc® uses the well-proven principle of attached growth rotating biological contactors (RBC), which support an active film (biomass) for biological treatment of the wastewater. The RBC stage is divided into two specific zones, the first acting as an anoxic reactor and the second as an aerobic reactor. The whole system, including the primary settlement tank, the RBC and the final settlement tank, are housed in a single GRP tank and arranged in such a way that flow attenuation becomes an integral part of every plant.

At the first stage of the treatment process, the wastewater enters the primary settlement tank. Here the solids are settled out and retained as sludge, which is drawn off periodically for disposal. The partially clarified liquor is then brought in contact with the anoxic stage of the RBC reactor where partial degradation of BOD and de-nitrification take place. The biomass in the anoxic stage also provides biological attenuation of organic pollutants, which are partially treated and degraded into much more readily treatable substrates for the aerobic RBC stage.

The downstream aerobic RBC stage is operated under plug flow conditions where BOD removal and nitrification take place. The KEE NuDisc® technology can be applied to different applications to achieve the desired final effluent quality. For instance, where phosphorous removal is required this is achieved by coagulating phosphorous out of the treated effluent at the end of the RBC stage.

The final clarifier is benched at the bottom to facilitate the consolidation of sludge which is then returned to the primary clarifier through the pump assisted hydrostatic sludge return system. In applications requiring de-nitrification, this is achieved by further treating the nitrified effluent in the anoxic zone of the treatment system.

KEE NuDisc® - R

Built-in Optional Tertiary Treatment

The treated effluent from the final clarifier can be discharged to a watercourse or, as an option, this can be further treated to a much higher quality in a physical-biological tertiary stage. This physical-biological filter includes media with extremely large surface area to volume ratio and is arranged in the unit to work as alternating aerobic and anoxic zones for the most effective breakdown of the residual organic constituents (hard BOD) of the treated wastewater from the first and second zone RBC process. The tertiary filter stage is fitted with natural wind turbine or electric fan assisted aeration zones for creating the alternating aerobic-anoxic stages in the filter. The tertiary stage media structure is such that the effluent undergoes breakdown of the remaining soluble organic material and the fine solids contained in the wastewater. The fine organic solids are captured and retained in the media for breakdown.

Effluent Disinfection:

The treated effluent from the compact KEE NuDisc® or KEE NuDisc®-R can be disinfected using packaged UV light disinfection system before discharge. The disinfected effluent can be either discharged to a watercourse or recycled for irrigation or other applications such as toilet flushing or non-portable use.

The KEE NuDisc® is offered for flows from 1m³/day through to 70m³/day and the KEE NuDisc®-R is offered for flows from 1m³/day through to 40m³/day and is normally packaged into a single piece structure with low profile aesthetically acceptable sectional GRP covers. They incorporate hatches that allow easy desludging and access to mechanical components for regular maintenance. This same KEE NuDisc® and KEE NuDisc®-R technology are also available as Modular RBC Systems, where the individual unit process operations are separated to provide greater flexibility in design, whilst retaining the essential design features such as Managed Flow and flow/load attenuation.

For additional information on NuDisc technology please visit the KEE website