“Septic tank regulations” – I agree it’s not an opening phrase that would make many people read on, but if you have a septic tank on your property, then you might just need to read on.

Given what goes into a septic tank, it’s understandable why the Environment Agency is keen to make sure that it stays in the tank, instead of in the local stream. So, there are a lot of rules and regulations surrounding septic tanks, from where you can put them to where and how the water can be discharged.

The latest regulations came out in 2015, and are called `General binding rules: small sewage discharge to surface water’. It doesn’t exactly trip off the tongue, but it’s a very important document for many property owners and worth a read.

In the past, you could discharge the separated waste water from your septic tank in one of two ways:

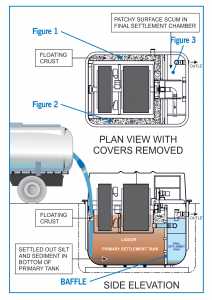

- To a drainage field or soakaway system – here, the waste water percolates through holes or slots from the pipework, into a soak away (pit filled with rubble or course stones) and then discharged into the surrounding sub-soils.

- To a watercourse – the waste water would flow through a sealed pipe straight to a local watercourse such as a stream or a river.

So, what’s changed?

From the 1st of January 2020, you will not be able to discharge your wastewater into a watercourse. The reason for this is because the `quality’ of the waste water is no longer considered clean enough for our wildlife or rivers.

This isn’t an entirely a new rule as for some years now, property owners installing a new septic tanks have not been able to discharge into a watercourse. However, if your property had an existing septic tank discharging into a watercourse, you were able to carry on unless the Environmental Agency identified that it was causing contamination.

So, if you are looking to sell your property between now and 2020 you will be required to ensure your Septic Tank meets the new regulations before you sell.

So what are the options?

There are three main ways in which you can comply with the new regulations:

- Connect to mains drainage system

- Install a sewage treatment plant – Sewage treatment plants clean and filter the wastewater to remove harmful toxins and impurities, making the wastewater clean enough to discharge straight into a watercourse.

- Install a drainage field or soakaway – This will take the waste water from your septic tank, and disperse it safely into the ground without causing pollution. However, space is required as a soakaway must be located at least 5 meters away from any property and at least 6 meters away from a Public Highway.

To conclude, if you do not have the space to install a soakaway on your land and are not close enough to a mains sewage system to get connected then a Sewage Treatment Plant is your best option.

For more guidance or a quote, please contact KEE on 01296 634 500 or email sales@keeservices.com.