Jen Carr who will be running 2 marathons in April for MakeAWishUK and is aiming to complete the Paris & London Marathons to raise money for them.

Jen Carr who will be running 2 marathons in April for MakeAWishUK and is aiming to complete the Paris & London Marathons to raise money for them.

Good luck Jen.

For full story about Jen and to make a donation please visit HERE.

Jen Carr who will be running 2 marathons in April for MakeAWishUK and is aiming to complete the Paris & London Marathons to raise money for them.

Jen Carr who will be running 2 marathons in April for MakeAWishUK and is aiming to complete the Paris & London Marathons to raise money for them.

Good luck Jen.

For full story about Jen and to make a donation please visit HERE.

The growing pressure to clean up Britain’s rivers to meet bathing water quality is a “game changer” that will require more government funding as the public embrace the outdoors.

Click for more information from The Guardian

Push for bathing water quality hailed as ‘game changer’ for UK rivers. Environment Agency boss calls for more funding to help public embrace wild swimming.

Visit our website for full information on Services and Technologies from the KEE Group of companies.

Spare a thought for your

Sewage Treatment Plant this Christmas

With the festive season upon us, guests arriving and the celebrations in full swing, please do keep in mind what you and any visitors are pouring or flushing down your drainage system into your Sewage Treatment Plant.

Do’s

Don’ts

Click the image to download the leaflet.

For more information visit our website or call

KEE Services on:

01296 634500

Back in November 2017, we wrote a blog advising all our customers of the change in Septic Tank Regulations which come into effect on the 1st January 2020. If you have a Septic Tank at home or at work and it’s discharging into a river, stream or surface water, we recommend that you take action now and review replacing it with a Wastewater Treatment Plant to meet the new EA regulations coming into force on the 1st January 2020.

Discharges from septic tanks directly to surface water will no longer be allowed under the general binding rules.

To help guide you on the new regulations, please read our last blog on the subject here and the click on the link to the current Gov.UK webpage on the subject here

KEE Process & KEE Services specialise in Wastewater Treatment Plants so if the changes in regulations apply to you then please do give us a call on 01296 634500 as soon as possible so we can help guide you through the process and advise you on the best approach to meet your requirements and EA regulations.

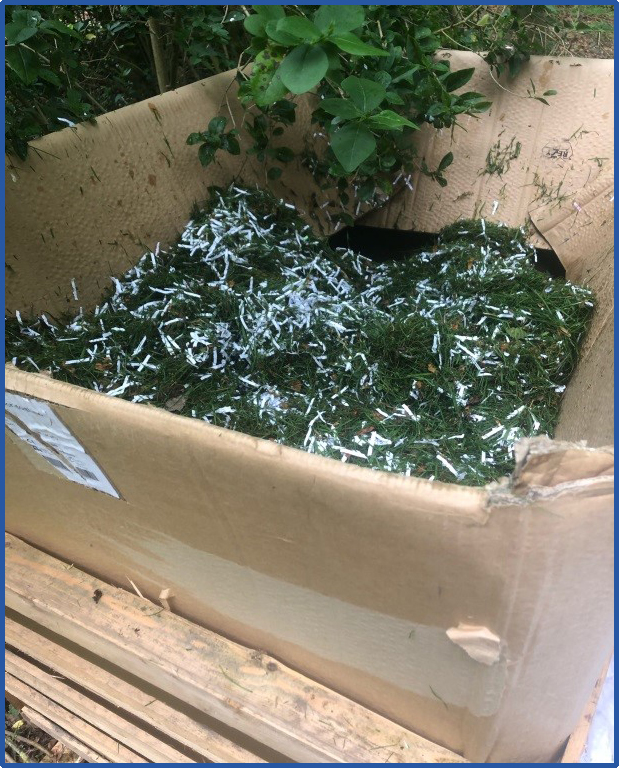

This month, we wanted to feature some examples showing the imaginative ways in which KEE’s waste shredded paper and pallets are being used in the local community to help improve the local environment.

Tom works for a company caring for cancer patients. He uses the shredded paper to help break up the soil mass in the gardens. As you will see from the picture he sent in, Tom mixes the shredded paper with grass cuttings and leaves it to mulch down ready for digging into the soil in Autumn. This helps to lighten the soil and improve its texture and absorbency.

Tom works for a company caring for cancer patients. He uses the shredded paper to help break up the soil mass in the gardens. As you will see from the picture he sent in, Tom mixes the shredded paper with grass cuttings and leaves it to mulch down ready for digging into the soil in Autumn. This helps to lighten the soil and improve its texture and absorbency.

Our waste shredded paper is also used by a local lady who takes in sick animals from a local vet and nurses them back to health at her home. She uses the paper for animal bedding to not only help keep the area nice and clean for the animals but it also provides a soft, cosy bed for them to sleep on at night! When the paper is soiled and needs changing, it all goes straight into the composter and is recycled once again.

Tom has also been busy recycling our pallets to make a fence around his allotment. There has been a lot of interest from local people wanting to recycle our pallets recently so hopefully; later on in the year we will be able to show you some more great examples of how our pallets have been used to create something new.

Tom has also been busy recycling our pallets to make a fence around his allotment. There has been a lot of interest from local people wanting to recycle our pallets recently so hopefully; later on in the year we will be able to show you some more great examples of how our pallets have been used to create something new.

Visit the keegroup website for full information on our services and technologies or phone 01296 634500.

The unrivalled knowledge, sound mechanical, electrical and process experience plus invaluable application knowledge enables our engineers to identify problems with equipment early on and recommend the best solution. They have been involved in long-term care of over 8000 installations, maintaining all types and makes of wastewater treatment equipment.

KEE Services have over 60 years of knowledge and expertise in servicing wastewater installations and can tailor the service we provide to meet your requirements.

Our nationwide team of directly employed Engineers operate on a local and regional basis ensuring they have all the understanding of the local area conditions and legislation.

To book a service visit or for more information please contact us at http://www.keeservices.com/book-a-service.html

Call +44 (0) 1296 634 500 or visit our KEE Services website.

![]()

KEE received a lovely ‘Thank You’ email this week from a wonderful local charity called Animal Antiks. KEE Group donated some fiberglass Wastewater Treatment Plant Covers to Animal Antiks so their young people and volunteers can enjoy making outdoor shelters for the animals to protect them from the rain and wind this winter.

Animal Antiks is a small local charity here in Buckinghamshire who support children and adults with a variety of difficulties and disabilities. They re-located from Aylesbury to a 200+ acre farm in North Marston in September 2017 and the charity use their expertise and experience along with their diverse collection of animals (many of which are rehomed or rescued) for animal assisted learning.

The charity supports individuals with mental health, emotional, behavioural and special educational needs and use a natural farm setting and interaction with animals to build confidence, improve key life and develop social and functional skills.

This local Buckinghamshire charity currently support over 40 adults and young people who attend from between an hour a week up to a full five days a week.

If you would like to show your support for this great local charity – please ‘like’ their facebook page https://www.facebook.com/animalantiks/.

You can also make a donation on this facebook page if you wish or alternatively contact Animial Antiks by email at animalantiks@yahoo.co.uk.

KEE would like to wish all our customers, suppliers and the team at Animal Antiks a very happy Christmas and a happy, healthy and prosperous 2019.

KEE Process Exports

This month, KEE Process exports another Wastewater Treatment Plant. This one pictured below has been exported for installation in the Grand Cayman Islands.

KEE Process are known worldwide as a reputable supplier of Wastewater Treatment Plants and our products are exported across the globe. Over the 60 years since the company was founded, we have also forged strong and lasting relationships with Global Agents operating in:

We would like to take this opportunity to thank all our Global Agents and customers around the world for their support and confidence in us as a supplier.

For more information on KEE exports and Global Agents, please visit our KEE Process website or contact our Head Office on 01296 634500.

It is imperative that a qualified ‘Slinger Banksman’ is in charge to direct and oversee the operations.

Adrian, Antonio and Luis in the yard, completing their training.

When KEE require the help of an external company to lift our bigger units on to the back of low loaders ,a 40 tonne or 50 tonne crane is required. When this takes place, the Slinger Banksman has to ensure that the lifting plan for the unit is carried out as specified. Any error in the lifting process can cause uneven pressure loads on to parts of the equipment so it is imperative that a qualified ‘Slinger Banksman’ is in charge to direct and oversee the operation. The Slinger Banksman guides the Crane Operator to where they need to be positioned whilst ensuring no other people come into the lifting area when a lift is taking place. Each lift involves positioning the lifting slings in the correct place and being in constant contact with the Crane Operator to ensure the lift is safe to complete.

We all at KEE look forward to seeing Adrian, Antonio and Luis out in the yard putting their training in to practice!

Visit the KEE Group Website

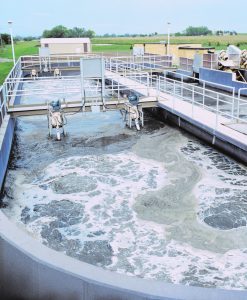

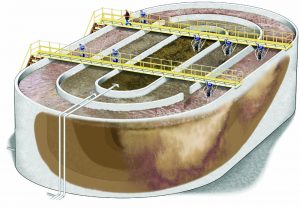

Oxidation ditch technology is one of the oldest ways of treating wastewater. Whilst it enables wastewater to be treated to a high standard, including nitrification and denitrification, it does have significant limitations.

The process requires aerated and mixed liquor to continuously move through the aeration ditch. Brush rotors and disc rotors aerate and mix the liquor but, because they can only maintain the necessary fluid velocity of 0.3 – 0.4 m/s in a shallow depth of no more than 2m, the footprint area of the oxidation ditch is extremely large.

The KEE Triton Aerator and Mixer Aerator is an energy efficient, dual mode (aeration and mixing) process aerator that is capable of nitrification and denitrification all in one unit. With two propellers and a regenerative blower, it is able to operate either as an anoxic mixer with the blower turned off, or a very efficient aerator/mixer with the blower turned on.

With its two mixing propellers, the Triton is able to achieve significant velocities in depths of up to 10m. This means the oxidation ditch basin can now be built up to 10m deep, therefore significantly reducing the footprint area.

The Triton Aerator/Mixer’s primary and secondary propellers inject air bubbles (defined by the Environmental Protection Agency as “fine bubble”) into a high velocity stream (plume) below the surface of the water and provide flow linkage mixing in multiple unit arrangements.

The Triton can also be used to revitalise existing oxidation ditch systems with failing brushes or disc rotors. If the rotors have totally failed, the Triton can replace them.

Oxidation Ditch with Nitrification, Denitrification and Aerobic Sludge Digestion.

Franklin’s plant has two oxidation ditch systems operating in parallel, each of which treats 4536 m³/day, with influent BOD of 185 mg/l and TSS of 90 mg/l. The Oxidation Ditch Wastewater Treatment Plant at Franklin was failing to meet the consent of 15mg/l BOD and 23 mg/l TSS. Because the rotors required daily lubrication, maintaining them was a time consuming and costly exercise. So when the rotors fractured and failed four years ago, the decision was made to upgrade the plant by replacing the brush rotors with the Triton Aerator/Mixer.

Triton Aerators at the Franklin Wastewater treatment Plant help to produce

an effluent BOD of 2 to 3mg/l.

During the upgrade each ditch was fitted with four Triton each rated 18.6 kW. This represents a maximum of just over 2 kWh of electrical energy per kg of BOD or 0.4 kWh/m³ flow.

The final effluent quality from the refurbished oxidation ditch is testimony to the excellence of the Triton. The result of the upgrade was final effluent with BOD of between 2 and 3 mg/l and TSS well below 15 mg/l. Independent velocity measurements at extremities are well above the minimum 0.3 m/sec, therefore guaranteeing that no solids deposit would develop in the basin. At the same time, maintenance requirements have been substantially reduced to a simple lubrication task once every six months.

Oxidation Ditch with Nitrification, Denitrification and Aerobic Sludge Digestion. The Triton with its two mixing propellers is able to to achieve significant velocities in depths of up to 10m. This means the oxidation ditch basin can now be built up to 10m deep, therefore significantly reducing the footprint area.

Oxidation Ditch with Nitrification, Denitrification and Aerobic Sludge Digestion. The Triton with its two mixing propellers is able to to achieve significant velocities in depths of up to 10m. This means the oxidation ditch basin can now be built up to 10m deep, therefore significantly reducing the footprint area.

Alternatively, if the rotors are still in good working order but the plant is failing to meet treatment objectives due to lack of dissolved oxygen and/or mixing of the oxidation ditch aerators, Triton can be used in conjunction with the rotors to improve dissolved oxygen levels and mixing.

To see the capabilities of the KEE Group of companies please visit the KEE Group website