KEE Wastewater Treatment and Disposal

KEE are a major supplier of process engineered treatment systems and have been heavily involved with Water Services and Local Councils in Ireland for supply and upgrade of wastewater treatment facilities. The applications vary from simple Municipal wastewater treatment plants providing basic treatment to supplying plants which are designed to produce very high quality effluent with phosphorus and total nitrogen reduction. In many cases the requirements are for less than 3 mg/l of ammoniacal nitrogen associated with less than 5mg/l BOD and Suspended Solids.

Having been involved with supplying many Municipal wastewater treatment plants in Northern Ireland for sites at Kinallen, Fivemiletown, Bergah, Ballinamallard, Fintona, Lisbellaw, Caledon, Lislea and many more, KEE are also working with Councils in Eire to upgrade treatment plants to facilitate discharge of highly polluted industrial effluent into their system.

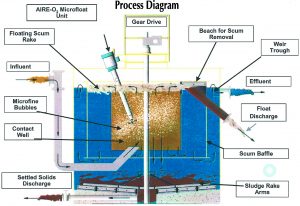

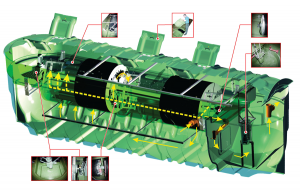

Municipal wastewater treatment plants are able to accommodate and treat industrial discharges if these are taken into account at the design stage. However, when the industrial discharge is intermittent and imposes sudden shock loads onto an otherwise overloaded Municipal facility, KEE have been able to offer solutions to overcome such problems. This includes upgrading the Municipal facility without much upheaval and also offering partial treatment of the industrial discharge at source to overcome the problems. This is particularly the case with Municipal facilities which become oxygen limited in the activated sludge stage. The solution is to install their versatile dual mode TRITON® processor which provides mixing and/or dissolved oxygen into the mixed liquor. It is also possible to use the KEE DISPERSED AIR FLOATATION (DAF) MICROFLOAT® SYSTEM to provide partial on-site treatment to the industrial discharge to reduce the load discharged into the sewer. KEE have used TRITON® Aerator to upgrade an overloaded Municipal plant in Scotland to accommodate loads generated from Distillery and are in the process of upgrading a Dairy Plant to upgrade the aeration system using TRITON® Aerator and to include biological phosphorus removal and reduce fat and grease by installing the KEE DAF system upstream of the biological process. “The polluter pays” and it therefore follows that those Industries which discharge large quantities of heavily polluted wastewaters into the sewer should consider the options of on-site treatment to reduce their costs and the loads on the Municipal treatment facilities. The treatment options which should be considered are Physical, Physical/chemical or biological treatment or a combination of all or any of these.

KEE MICROFLOAT® SYSTEM

KEE MICROFLOAT® SYSTEM

KEE TRITON® AERATION/MIXING

KEE TRITON® AERATION/MIXING

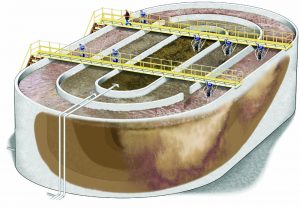

KEE have built many facilities in Ireland to include phosphorus and total nitrogen removal with simplicity of process design and operation thus embracing the KEE philosophy of offering low lifetime cost solutions.

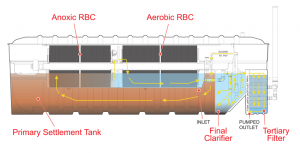

The KEE Group of Companies, can offer such an option. Their technologies include physio-chemical processes (Dispersed Air Floatation, simple gravity solids and grease separators), Anaerobic Reactors (for high strength wastewaters), Fixed Film Reactors (RBC & SAF) and Suspended Growth Reactors (activated sludge processes -Extended Aeration, Oxidation Ditch, SBR, Extended Aeration followed by Ultra Fine Filtration), and on-site operation of the treatment plant. KEE also have a team of experienced process engineers and project engineers capable of delivering the necessary turnkey solution to suit most customers.

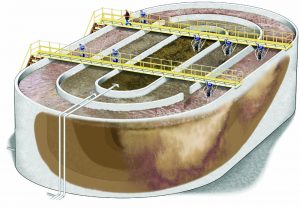

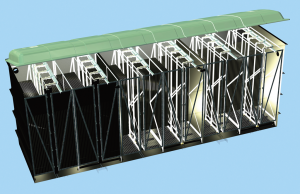

OXIDATION DITCH KEE ENVIROSAF

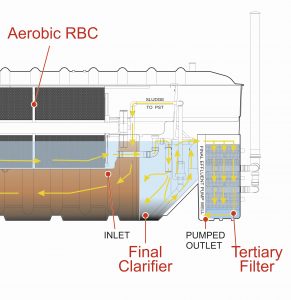

O KEE ROTATING BIOLOGICAL CONTACTORS (RBC)

KEE ROTATING BIOLOGICAL CONTACTORS (RBC)

To see the capabilities of the KEE Group of companies please visit the KEE Group website

KEE is a globally recognised brand operating within in the industrial, commercial and domestic wastewater treatment industries. KEE’s specialist knowledge and expertise is derived from over 60 years’ experience in the design, development, manufacture, install, commissioning, operation, refurbishment, repair and maintenance of wastewater treatment systems and equipment, including:

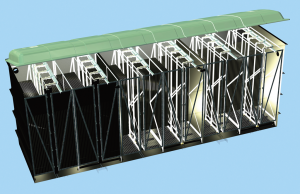

- Fixed Film Reactors: Rotating Biological Contactors (RBCs), Packaged RBC Systems, Moving Bed Biological Reactors (MBBR) and Submerged Aerated Filters (SAF).

- Suspended Growth Reactors: Extended Aeration, Sequencing Batch Reactor (SBR), Oxidation Ditch, IFAS process technologies and Anaerobic Biological Reactor (ABR) for high strength industrial waste.

- ‘Turn Key’ Solutions: Technical Design, Project Appraisal & Management, Process Engineering, Plant Installation & Operation, Equipment Refurbishment & Upgrades and Plant Rental. KEE also provide approved spares and ancillary products such as Final Clarifiers and Settlement Tanks.

KEE Services Ltd specialise in maintenance & repair services for all makes and types of wastewater treatment systems & pumping stations. Our nationwide team of directly employed, regional engineers and technicians are KEE trained, DBS checked and British Water Certified.